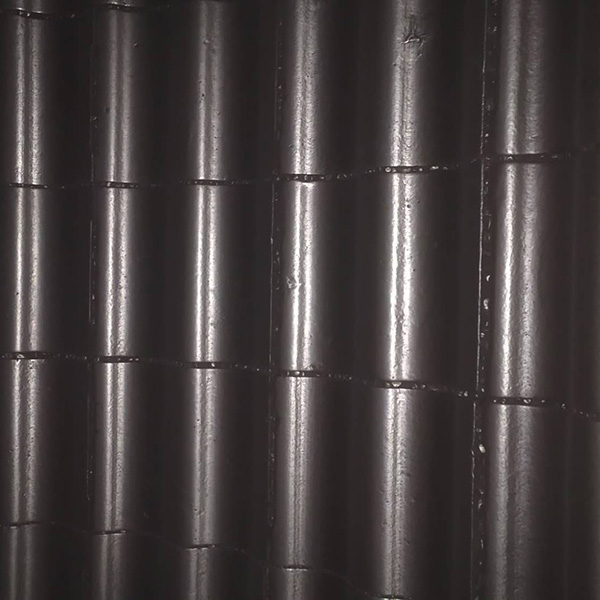

26% Cr 28% Cr High Cr Sib Tsoo Zeb Liner

Lus piav qhia luv luv:

Product Description

Dawb Hlau Pob Zeb Liner feem ntau yog hais txog cov hlau dawb hlau nrog cov ntsiab lus chromium ntawm 12% ~ 26%, cov ntsiab lus carbon ntawm 2.0% ~ 3.6%. Dawb Hlau Pob Zeb Liner qhov tshwj xeeb yog tias M7C3 hom eutectic carbide micro hardness yog HV1300 ~ 1800. Dawb Iron Ball Mill Liner's eutectic carbide yog faib rau ntawm lub hauv paus, martensite (lub koom haum nyuaj hlau matrix), nyob rau hauv kev sib txuas tsis tu ncua thiab kev sib cais, uas txo cov fragmentation ntawm cov nyhuv matrix. Yog li ntawd, lub siab chromium Pob Zeb Liner muaj lub zog siab, muaj zog toughness thiab zoo hnav tsis kam, uas yog dav siv hauv Mining, Cement thiab fais fab kev lag luam.

Dawb Iron Ball Mill Liner tau pom zoo kom siv thaum muaj kev cuam tshuam tsis zoo rau kev ua haujlwm xws li:

1. Siv conveyor liner rau Mining kev lag luam.

2. Cement cog Pob Zeb.

3. Tshuaj lom neeg kev lag luam Pob Zeb.

Chemical Elements

|

Lub npe |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High Cr Pob Zeb Liner Cr26 |

2.5-3.3 |

0-0.8 hli |

≤ 2.0 |

23-28 : kuv |

≤3.0 |

≤1.2 |

≤ 0.06 |

≤ 0.06 |

|

High Cr Pob Zeb Liner Cr15 |

2.3-3.3 |

0-0.8 hli |

≤ 2.0 |

14—18 |

≤3.0 |

≤1.2 |

≤ 0.06 |

≤ 0.06 |

Physical Property & Microstructure

|

Lub npe |

HRC |

Ak(J/cm2) |

Microstructure |

|

High Cr Pob Zeb Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C-Carbide A-Austenite |

|||

Lus Cim: Kho cov ntsiab lus tshuaj los yog ntxiv lwm cov ntsiab lus alloying ntawm Pob Zeb Liner raws li cov neeg siv khoom xav tau.

Pob khoom

● Hlau Pallet, Ntoo Pallet thiab Ntoo Box

● Customized raws li kev ntim khoom tshwj xeeb.

Daim ntawv thov

Peb Cov Hlau Hlau Pob Zeb Liner tau siv dav hauv kev sib tsoo theem rau kev lag luam mining, cement kev lag luam, thermal fais fab nroj tsuag, ntawv-ua thiab tshuaj lom neeg kev lag luam thiab lwm yam.

Lub pob zeb yog ib hom kev sib tsoo siv los sib tsoo, sib tov thiab qee zaum rau kev sib xyaw ntawm cov khoom siv rau hauv cov txheej txheem hnav khaub ncaws, xim, pyrotechnics, ceramics thiab xaiv laser sintering. Nws ua haujlwm ntawm lub hauv paus ntsiab lus ntawm kev cuam tshuam thiab attrition: txo qhov luaj li cas yog ua los ntawm kev cuam tshuam raws li cov khoom poob los ze rau saum lub plhaub.

Lub pob zeb muaj lub hollow cylindrical plhaub rotating txog nws axis. Lub axis ntawm lub plhaub yuav yog kab rov tav lossis ntawm lub kaum me me rau kab rov tav. Nws yog ib nrab ntim nrog pob. Cov xov xwm sib tsoo yog cov pob, uas tuaj yeem ua los ntawm cov hlau (chrome steel), stainless hlau, ceramic lossis roj hmab. Sab hauv ntawm lub plhaub cylindrical feem ntau yog lined nrog cov khoom siv tsis zoo xws li manganese steel lossis roj hmab hauv ob sab phlu. Tsawg hnav tshwm sim hauv cov roj hmab lined mills. Qhov ntev ntawm lub zeb yog kwv yees li sib npaug rau nws txoj kab uas hla.

Thaum nws los txog rau chrome moly dawb hlau zeb liners, H&G Mill Liners tau tsom cov khoom siv no ntev. Peb chrome moly dawb hlau zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom cam khwb cia no suav hais tias yog qhov kawg tsim thiab siv rau hnub rau kev puas tsuaj hauv Milling. Nws yog feem ntau siv nyob rau hauv cov cement mills thiab qee qhov loj tshaj plaws Pob Zeb Mills nyob hauv lub ntiaj teb thiab qhov chaw ua haujlwm tsis tau zoo dua rau hnub tim.

Cov yam ntxwv

- 600 rau 700 BHN dawb hlau

- Cov pob zeb loj

- Malleable Iron: cam khwb cia li dawb hlau, ces malleabilised, los yog kub kho, impart ductility. Nws muaj tempered graphite nyob rau hauv ib tug-ferrite los yog pearlite

matrix - Feem ntau hauv cov cement mills

- Siv rau abrasion tsis kam

Thaum nws los txog rau Ni-hard hlau zeb liners, H&G Mill Liners tau tsom mus nrum cov khoom no rau peb cov neeg siv khoom. Peb Ni-hard hlau zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Ni-Hard Cam khwb cia hlau yog paub zoo rau nws cov kav ntev thiab zoo. Cov ntaub ntawv ua los ntawm Ni-Hard yog hnav resistant thiab muaj lub neej ntev piv rau lwm yam cam khwb cia hlau los yog hlau me me. Nickel cov ntsiab lus nce nrog ntu loj lossis lub sijhawm txias thiab tiv thaiv pearlitic hloov pauv ntawm cov cam khwb cia hlau.

Cov khoom siv no Kev siv cov khoom siv no feem ntau pib nrog Qws Mills thiab Pob Zeb, qhov kev cuam tshuam tau txiav txim siab tsawg txaus rau cov khoom no nkig tsis tau zoo heev abrasive resistant hnav kom ua tau zoo. Txawm li cas los xij, tam sim no nws tau suav tias yog qhov tsis siv nyob rau hauv lub teeb ntawm kev siv cov hlau chrome siab thiab chrome moly dawb hlau.

Nta

- Chromium feem ntau suav nrog ntawm 1.4-4% kom ntseeg tau tias carbon theem solidifies rau carbide, tsis graphite. (Tawm tsam cov nyhuv graphitizing ntawm Ni);

- Abrasion kuj (feem ntau xav tau cov cuab yeej ntawm cov khoom no) nce nrog cov ntsiab lus carbon, tab sis toughness txo;

- Muaj martensite matrix, nrog npib tsib xee alloyed ntawm 3-5% txhawm rau txhawm rau txhawm rau hloov pauv ntawm austenite rau pearlite;

- Abrasion kuj (feem ntau xav tau cov cuab yeej ntawm cov khoom no) nce nrog cov ntsiab lus carbon, tab sis toughness txo;

- Ntau qib kawm kuv hom A puas resistant; Class I hom B toughness;

- Daim ntaub ntawv: Vim yog tus nqi qis, siv feem ntau hauv kev siv mining ua pob zeb liners thiab sib tsoo pob;

- Cov khoom siv hardness: 550 BHN

Thaum nws los txog rau qis carbon chrome moly steel zeb liners, H&G Mill Liners tau tsom mus nrum cov khoom no rau peb cov neeg siv khoom. Peb cov pa roj carbon tsawg chrome moly steel zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom no tseem hu ua AS2074 L2B steel.Cov hlau no feem ntau yog siv rau cov pob zeb (AG, SAG thiab Pob) ua ntej txav mus rau cov ntsiab lus carbon ntau dua. Nws muaj cov yam ntxwv zoo heev nrog rau qee qhov kev cuam tshuam, feem ntau tam sim no siv rau kev tso tawm grate qhov twg yuav tsum muaj kev cuam tshuam zoo dua me ntsis piv rau cov pa roj carbon monoxide siab dua lossis rau cov kab nyias nyias.

Nta:

- Siv rau AG / SAG thiab pob zeb;

- Cov yam ntxwv zoo heev hnav thiab qee qhov cuam tshuam tsis kam;

- Metallographic qauv ntawm AS2074 L2B Steel yog Pearlitic;

- Zoo rau kev tso tawm grate;

- Lub hardness ntawm AS2074 L2B yog HB310-HB380.

Thaum nws los txog rau siab carbon chrome moly steel zeb liners, H&G Mill Liners tau tsom mus nrum cov khoom no rau peb cov neeg siv khoom. Peb lub siab carbon chrome moly steel zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom no tseem hu ua AS2074 L2C steel.This steel yog tam sim no suav hais tias yog cov khoom tseem ceeb siv rau SAG zeb liners. Muaj ntau qhov kev hloov pauv nrog cov ntsiab lus sib txawv ntawm cov pa roj carbon lossis chrome. Cov variations yuav muaj ib tug bearing ntawm qhov loj ntawm lub liner thiab nws seem thickness. Muaj kev txhim kho tsis tu ncua nyob rau hauv cheeb tsam no raws li qhov loj ntawm cov liners yog outstripping cov khoom muab los ntawm tus qauv siab chrome moly steels.

Nta

- Cov khoom siv ntawm SAG zeb liners yog qis C lossis siab C Cr-Mo Alloy steel, uas nyob ntawm qhov tshwj xeeb ua haujlwm ntawm SAG zeb;

- Chromium thiab molybdenum ob leeg ib leeg zuj zus ntxiv hardenability ntawm cov hlau tsis tshua muaj hlau. Cov teebmeem tseem ceeb ntawm kev sib koom ua ke, tseem tsis tau txhais tag nrho, tuaj yeem tshwm sim thaum Cr thiab Mo siv rau qhov chaw ntawm ib lub ntsiab lus;

- Metallographic qauv ntawm AS2074 L2C Steel yog Pearlitic;

- Chromium ua rau muaj kev tiv thaiv corrosion thiab oxidation, kub siab zog thiab abrasion kuj. Molybdenum pab tswj cov txheej txheem hardenability thiab ua kom kub siab tensile thiab creep zog. Cov qib no feem ntau raug kho kom sov rau cov khoom tshwj xeeb;

- Cov khoom siv hardness: 325-380 BHN

Ball Mill Liner Installation Requirements

- Tom qab lub zeb liner tau teeb tsa, qhov kawg hauv ob sab phaj thiab lub tog raj kheej kawg npog yuav tsum tau ntim nrog compressive zog qib 43.5MPa cement mortar.

- Cov bolts kho qhov kawg liner yuav tsum tsis txhob cia cov cement mortar txaus, tab sis yuav tsum tau tig los yog nkag mus thiab tawm.

- Lub pob zeb hauv ob sab phlu feem ntau yog kev taw qhia, koj yuav tsum tau them sai sai rau nws thaum lub sijhawm teeb tsa, tsis txhob thim rov qab.

- Lub arc ntev ntawm tag nrho cov hlaws hlaws yuav tsum tsis pub tshaj 310mm, thiab cov tshaj yuav tsum tau wedged nrog steel daim hlau kom cais nws.

- Qhov sib txawv ntawm cov kab uas nyob ib sab yog tsis ntau tshaj 3 ~ 9mm.

- Lub interlayer yuav tsum tau muab tso rau raws li tus qauv tsim ntawm lub liner thiab sab hauv ntawm lub tog raj kheej. Yog tias tsis muaj qhov yuav tsum tau ua, cov cement mortar nrog lub zog compressive ntawm 42.5MPa tuaj yeem ua tiav ntawm ob. Tom qab cov cement mortar tau teeb tsa, nruj cov liner bolts dua.

- Thaum txhim kho lub liner nrog roj hmab ncoo, qhib cov ntawv coiled roj hmab 3 mus rau 4 lub lis piam ua ntej kev teeb tsa kom tso cai rau nws ncab dawb; Thaum siv cov ntawv roj hmab, sab ntev ntawm daim ntawv roj hmab yuav tsum ua raws li cov kev taw qhia axial ntawm lub tog raj kheej, Lub sab luv ua raws li qhov ncig ntawm lub tog raj kheej.

- Ua tib zoo xyuas cov qhov ntsia hlau qhov thiab cov geometry ntawm lub liner bolts, thiab ua tib zoo ntxuav lub flash qhov, burrs, thiab protrusions ntawm lub liner bolt qhov thiab lub liner bolts thiaj li hais tias cov bolts tuaj yeem nkag mus rau hauv txoj haujlwm xav tau.

- Cov txheej txheem tag nrho yuav tsum muaj cov ntsia hlau ntsia hlau, cov tshuab ntxhua khaub ncaws, cov ntxhua khaub ncaws, lub caij nplooj ntoos hlav ntxhua khaub ncaws, thiab cov txiv ntoo; txhawm rau tiv thaiv cov hmoov tshauv, koj yuav tsum tsis txhob hnov qab siv cov plua plav plua plav thaum siv.

- Thaum zawm cov bolts hauv ob sab phlu, yuav tsum siv lub torque wrench rau kev ua haujlwm. Nyob rau hauv ob sab phlu bolts ntawm txawv specifications yuav tsum tau nruj me ntsis raws li tus coj nruj torque yuav tsum tau.