Cement Sib Tsoo Pob Zeb Siv Sib Tsoo Media Pob Casting Hlau Sib Tsoo Pob Casting Hlau Pob

Lus piav qhia luv luv:

Product Description

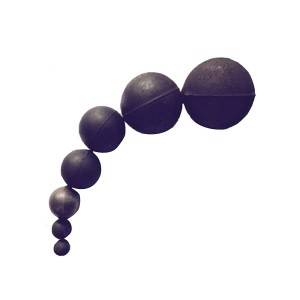

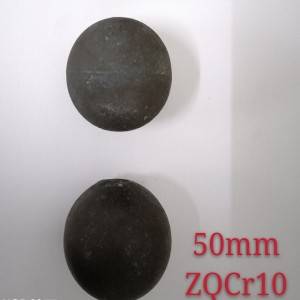

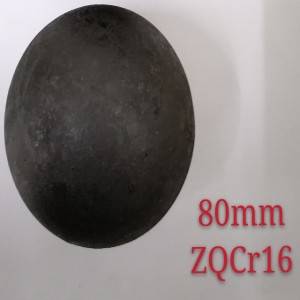

Cement Sib Tsoo Pob Loj ntawm 12-125 mm, 45-65 HRC, 1-23% Cr. cov ntsiab lus.

Cement Sib Tsoo Cylpeb ntawm qhov ntau thiab tsawg 45-65 HRC, 1-23% Cr. cov ntsiab lus.

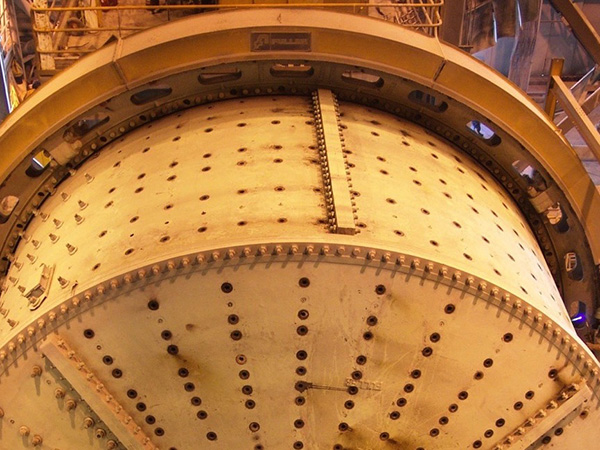

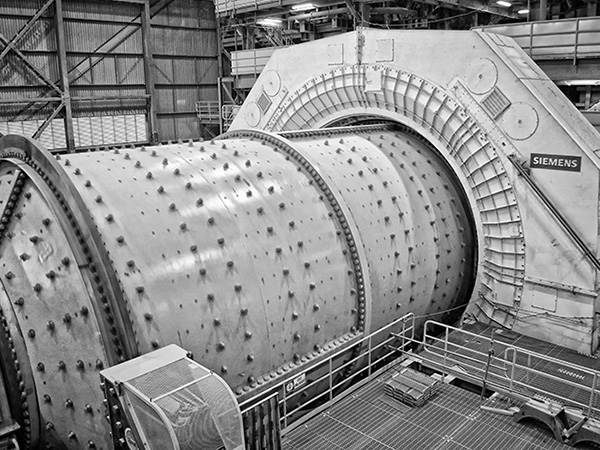

Lub Sib Tsoo Media Sib Tsoo Pob yog tsim los ntawm tag nrho-Auto casting kab, tau lees paub raws li cov qauv zoo thoob ntiaj teb.

Peb lav peb Cement Sib Tsoo Pob muaj tus nqi tawg qis, txo qis kev noj, thiab cov nqe lus xa khoom sai.

Specification Muaj

|

Lub npe |

Chemical Element (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Sib Tsoo Pob thiab Sib Tsoo Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 hli |

10-23 |

0-3.0 Nws |

0-1.2 hli |

≤ 0.06 |

≤ 0.06 |

|

Low-Cr Alloyed Sib Tsoo Pob thiab Sib Tsoo Cylpeb |

1.8-3.6 |

≤1.5 |

0.3-1.5 hli |

1-6 |

0-1.0 Nws |

0-0.8 hli |

≤ 0.06 |

≤ 0.06 |

Physical Property & Microstructure

| Lub npe |

Hardness (HRC) |

Kev cuam tshuam Ak (J / cm 2) |

Microstructure |

Lub Sijhawm Caij Nplooj Ntoos Hlav |

||

|

High-Cr Alloyed Sib Tsoo Pob thiab Sib Tsoo Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥ Φ80 |

≥10000 |

|||||

|

Low-Cr Alloyed Sib Tsoo Pob thiab Sib Tsoo Cylpeb |

≥45 |

≥2.5 |

P + C |

≤Φ80 |

≥12000 |

|

|

≥ Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Sib tsoo pob Specification

|

Loj (mm) |

Qhov hnyav (kg) |

Ntim (pc / t) |

|

Loj (mm) |

Qhov hnyav (kg) |

Ntim (pc / t) |

|

Φ17 |

0.027 ib |

37037 |

Φ70 |

1.37 ib |

729 |

|

|

Φ20 |

0.032 ib |

31250 |

Φ80 |

2.05 Nws |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 ib |

345 |

|

|

Φ40 |

0.25 ib |

3891 |

Φ100 |

4.00 Nws |

250 |

|

|

Φ50 |

0.50 ib |

2000 |

Φ110 |

5.30 Nws |

188 |

|

|

Φ60 |

0.86 ib |

1153 |

Φ120 |

6.80 ib |

147 |

Pob khoom

● Nylon Ton Hnab: Net Nyhav: 1000 kgs; Qhov hnyav tag nrho: 1002kgs

● Steel Nruas: Net Nyhav: 850 - 900 kgs; Qhov hnyav tag nrho: 865 - 915 kgs

Daim ntawv thov

Cov pob zeb sib tsoo yog siv los sib tsoo lossis sib xyaw cov ntaub ntawv. Lub pob zeb sib tsoo ua haujlwm ntawm lub hauv paus ntsiab lus ntawm kev cuam tshuam thiab attrition. Cov pob ua ntej tau tsim los ntawm cov hlau, ceramic lossis roj hmab. Niaj hnub no lawv muaj ntau yam kev tshawb fawb thiab Magotteaux tsim lawv nyob rau hauv cov alloys tshwj xeeb tshaj yog haum rau cov dej num uas lawv yuav tsum tau ua kom tsim tsawg hnav thiab ntau dua efficiency nyob rau hauv ntau lawm. Peb yuav muab tswv yim rau koj txog cov pob twg zoo tshaj plaws rau koj cov kev xav tau tshwj xeeb.

Kev xaiv ntawm kev sib tsoo xov xwm sib tsoo pob yuav ib txwm nyob ntawm cov khoom siv los ua hauv av. Koj yuav tsum ntsuas nws cov granulometry thiab cov txheej txheem sib tsoo. Koj kuj yuav tsum tau saib cov txheeb ze tseem ceeb ntawm cov txheej txheem hnav hauv cov txheej txheem.

High-Chrome sib tsoo xov xwm sib tsoo pob sib txuas cov qauv martensitic nrog nyuaj chrome carbides, Qhov no muab qhov zoo tshaj plaws hnav tsis kam tiv thaiv corrosion thiab puas ntawm txhua yam. HG qhov kev txawj ntse ua rau lawv xaiv cov hlau uas haum rau koj daim ntawv thov zoo kawg nkaus thiab txo cov nqi. High-Chrome sib tsoo xov xwm sib tsoo pob muaj qhov ua tau zoo tshaj plaws thiab tsim cov milling tsis tu ncua vim nws qhov hnav qis. Rau txhua qhov tshwj xeeb alloy muaj qhov hardness tas li ntawm txhua qhov sib tsoo xov xwm sib tsoo pob. Qhov no ua rau muaj kev cuam tshuam zoo hauv cov txheej txheem qis qis. high-Chrome sib tsoo xov xwm sib tsoo pob yog tsim rau ob qho tib si ntub thiab qhuav ore siv hauv kev sib tsoo pob zeb thiab sib tsoo ntauwd mills.