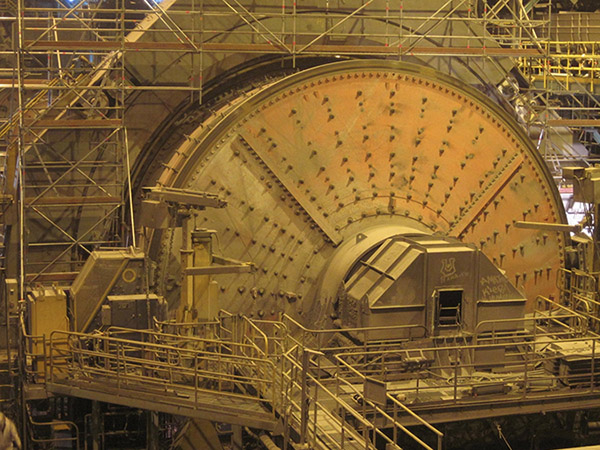

SAG thiab AG Mill FE Inner thiab Outer Mill Liner

Lus piav qhia luv luv:

Product Description

SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner los ntawm H&G siv Cr-Mo cov ntaub ntawv (AS2074 Standard), SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner muab kev cuam tshuam zoo dua thiab hnav tsis kam nyob rau hauv tag nrho cov semi-autogenous milling. daim ntawv thov.

Txhawm rau xaiv cov khoom tsim nyog rau daim ntawv thov raug yog peb lub luag haujlwm, peb ib txwm ua haujlwm ua ke nrog peb cov neeg siv khoom kom ua tiav qhov no .Cov ntaub ntawv raug yog raws li:

1. Cov pob zeb hauv av

2. Milling cov ntaub ntawv xov xwm

3. Qhov siab tshaj plaws sib tsoo media txoj kab uas hla (mm)

4. Sib tsoo media filling degree (%)

Feem ntau, Yam khoom M1 siv rau qhov muaj feem cuam tshuam loj, P1 siv rau qhov tsis zoo. Nws yuav tsum hloov raws li koj cov ntxhia ua.

Specification Muaj

|

Code |

Chemical Elements (%) SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 hli |

0.4-0.7 hli |

0.6-1.0 |

1.8-2.5 Nws |

0.25-0.5 hli |

0-0.5 hli |

≤ 0.04 |

≤ 0.06 |

|

M1 |

0.3-0.45 Nws |

0.4-0.7 hli |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 hli |

0-0.5 hli |

≤ 0.04 |

≤ 0.06 |

Physical Property & Microstructure

|

Code |

Hardness (HB) |

Ak (J / cm2) |

Microstructure |

|

P1 |

325-375 : kuv |

≥50 |

P |

|

M1 |

350-400 Nws |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Lus Cim: Kho cov ntsiab lus tshuaj los yog ntxiv lwm cov ntsiab lus alloying ntawm SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner raws li cov neeg siv khoom xav tau.

Pob khoom

● Hlau Pallet, Ntoo Pallet thiab Ntoo Box

● Customized raws li kev ntim khoom tshwj xeeb.

Peb Qhov Zoo

Ntawm H&G Casting, peb tsim cov qauv tsim tshiab, tshwj xeeb tshaj yog rau txhua tus neeg siv khoom. Peb SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner yog tsim los rau cov qauv kev lag luam siab tshaj plaws rau Autogenous Sib Tsoo (AG), Semi-Autogenous Sib Tsoo (SAG), Thawj / Secondary thiab rov sib tsoo pas nrig lossis pob zeb. MGS Casting zeb hauv ob sab phlu tsim los ntawm peb cov kev kawm tau zoo, thiab pab pawg neeg mob siab rau thoob plaws ntiaj teb tau coj koj tag nrho cov kev sib txuas ua ke rau hauv kev txiav txim siab. Txhawb nqa peb cov kab pem hauv ntej Mill Engineers yog ib pab pawg loj ntawm cov kws tsim qauv tsim tshwj xeeb, cov khoom siv chemists, kev tsim khoom thiab cov kws tshaj lij logistics lub luag haujlwm rau kev xa cov kev pabcuam tshwj xeeb.

Optimal zeb designs engineered los ntawm peb pab neeg coj mus rau hauv kev xav txog kev pab cuam lub neej; grind & zog efficiency thiab ore yam ntxwv, nrog rau cov neeg siv khoom Circuit Court txwv ob qho tib si nce thiab nqis ntawm lub zeb hauv ob sab phlu.

H&G Casting tau ua tiav los siv ASTM 2074 / L2B alloy steel los tsim AG / SAG zeb liners. Nyob rau hauv cov ntaub ntawv no, peb lub zeb liners ncua lub neej yuav ua kom pom tseeb. Peb cov neeg siv khoom Australia tau xaj ntau dua 10,000 tons hauv ib xyoos ntawm cov khoom siv zeb no.

Raws li qhov chaw tsim khoom, H&G Casting kuj muaj tus kheej SAG Semi-Autogenous Sib Tsoo Zeb Liner thiab AG Autogenous Sib Tsoo Zeb Liner tsim. Nyob rau hauv dav dav, lifter spacing thiab lub kaum sab xis, grate qhib cheeb tsam thiab aperture loj, thiab pulp lifter tsim thiab muaj peev xwm yuav tsum tau txiav txim siab. Txhua yam ntawm cov ncauj lus no tau muaj ntau qhov kev tshawb fawb, thiab ntau cov ntaub ntawv tshawb fawb ntawm evolutionary liner tsim tau luam tawm. Raws li kev paub dhau los, zeb liner tsim tau txav mus rau ntau lub plhaub lifter volumetric muaj peev xwm thiab kev tsim grate los pab txhawb kev siv ob qho tib si pebble-crushing Circuit Court siv thiab SAG zeb muaj peev xwm. Mill throughput yog maximized nrog plhaub lifters ntawm qhov sib piv ntawm 2.5: 1 thiab 5.0: 1. Qhov kev piv txwv no tau teev tseg yam tsis siv rau lub ntsej muag lub ntsej muag; Ntawm qhov sib npaug sib npaug-rau-qhov siab qhov sib piv, cov neeg nqa khoom nrog lub ntsej muag lub ntsej muag ntau dua yuav muaj teeb meem ntim tsawg dua thaum tshiab tab sis muaj kev hnav ris tsho ntau dua li cov uas muaj lub ntsej muag lub ntsej muag. Pulp lifter tsim tuaj yeem yog qhov tseem ceeb rau SAG mills, tshwj xeeb tshaj yog rau cov zeb loj. Tag nrho cov zeb loj loj nce, qhov yuav tsum tau muaj peev xwm ntawm cov pulp lifters loj hlob proportionally rau zeb ntim.

Semi-autogenous sib tsoo zeb liner kuj hu ua SAG zeb liner, Autogenous sib tsoo zeb liner kuj hu ua AG zeb liner. Txij li thaum xyoo 2014, H&G Machinery tau dhau los ua ib lub tuam txhab loj tshaj plaws AG / SAG zeb liner los ntawm Tuam Tshoj. Tsis muaj teeb meem dab tsi koj xav tau, manganese steel lossis Ni-hard steel lossis Cr-Mo steel lossis hlau alloy; Tsis muaj teeb meem yam twg ntawm koj cov mill liners xav tau. yoj duab los yog tsa ntug zoo los yog stepped zoo; H&G Machinery yog koj thawj qhov kev xaiv.

Dab tsi Xaiv H&G Machinery's AG / SAG Mill Liners?

- Kev paub nplua nuj. H&G Machinery muab ntau tshaj 10,000 tons ntawm ntau hom zeb liners.

- Ntau yam khoom siv. Peb muab cov ntaub ntawv sib txawv kom haum rau cov haujlwm sib txawv. Xws li manganese steel, Ni-hard steel, Cr-Mo steel, thiab lwm yam hlau alloys.

- Ua kom tiav QC system. H&G Machinery muab cov kev tswj xyuas kom zoo thiab cov ntaub ntawv sau tseg. Koj tuaj yeem tshawb xyuas tag nrho cov ntaub ntawv thiab cov ntaub ntawv thaum koj tuaj xyuas peb lossis peb xa tuaj rau koj.

- Kev pabcuam OEM. H&G Machinery tuaj yeem tsim koj cov ntaub los ntawm koj tus qauv tsim lossis peb tus kws tsim qauv tsim.

Thaum nws los txog rau austenitc manganese steel zeb liners, H&G Mill Liners tau tsom cov khoom siv no ntev. Peb cov austenitc manganese steel zeb liners ncua lub neej ntau tshaj li lwm cov foundries zeb liners.

Cov khoom siv no siv rau daim phiaj kab, thiab feem ntau me me mills. Nws qhov txiaj ntsig zoo yog tias nws ua haujlwm nyuaj hauv kev ntxhov siab, tab sis lub substrate tseem tawv thiab tuaj yeem tiv taus qhov cuam tshuam loj heev yam tsis muaj pob txha. Nws lub ntsiab qhov tsis zoo yog tias nws kis tau los ntawm kev cuam tshuam, yog li cov khoom siv hauv tsev pib nyem ua ke thiab dhau los ua qhov nyuaj rau tshem tawm, thiab tuaj yeem ua rau lub plhaub zeb puas yog tias qhov kev ntxhov siab raug tso cai los tsim kom muaj qib siab heev.

Austenitic manganese steel lub peev xwm ua hauj lwm nyuaj los ntawm kev cuam tshuam kev thauj khoom nrog rau nws qhov tshwj xeeb toughness ua rau nws yog qhov zoo tshaj plaws hnav cov khoom xaiv rau ntau qhov kev thov.The hardness ntawm manganese steel nyob rau hauv cov tshuaj annealed thiab dej quenched mob yog ib txwm nyob ib ncig ntawm 220 HB. Nws muaj peev xwm strain harden cov ntaub ntawv no mus rau kwv yees li 500 HB. Yuav kom ua tiav qib siab hardness no, qhov cuam tshuam rau kev thauj khoom yuav tsum siab thaum cov khoom hnav kom deb ntawm gouging abrasion yog txwv. Nws yog ib qho tseem ceeb nyob rau hauv crushing daim ntaub ntawv yog lub ntsiab hnav mechanism yog gouging abrasion uas cov manganese hlau yuav harden rau qee theem nrab, feem ntau 350-450 HB.

Thaum nws los txog rau qis carbon chrome moly steel zeb liners, H&G Mill Liners tau tsom mus nrum cov khoom no rau peb cov neeg siv khoom. Peb cov pa roj carbon tsawg chrome moly steel zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom no tseem hu ua AS2074 L2B steel.Cov hlau no feem ntau yog siv rau cov pob zeb (AG, SAG thiab Pob) ua ntej txav mus rau cov ntsiab lus carbon ntau dua. Nws muaj cov yam ntxwv zoo heev nrog rau qee qhov kev cuam tshuam, feem ntau tam sim no siv rau kev tso tawm grate qhov twg yuav tsum muaj kev cuam tshuam zoo dua me ntsis piv rau cov pa roj carbon monoxide siab dua lossis rau cov kab nyias nyias.

Chrome Moly Steel Chemical Composition

| Khoom Qib | C | Si | Mn | P | S | Cr | Mo |

| TIAB SA 2074 L2B | 0.55-0.65 Nws | <0.75 | 0.50-1.00 Nws | <0.06 | <0.06 | 0.80-1.50 Nws | 0.20-0.40 Nws |

| TIAB SA 2074 L2C | 0.70-0.90 Nws | <0.75 | 0.50-1.20 Nws | <0.06 | <0.06 | 1.30-2.40 Nws | 0.20-0.40 Nws |

Nta

- Siv rau AG / SAG thiab pob zeb;

- Cov yam ntxwv zoo heev hnav thiab qee qhov cuam tshuam tsis kam;

- Metallographic qauv ntawm AS2074 L2B Steel yog Pearlitic;

- Zoo rau kev tso tawm grate;

- Lub hardness ntawm AS2074 L2B yog HB310-HB380.

Thaum nws los txog rau siab carbon chrome moly steel zeb liners, H&G Mill Liners tau tsom mus nrum cov khoom no rau peb cov neeg siv khoom. Peb lub siab carbon chrome moly steel zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom no tseem hu ua AS2074 L2C steel.This steel yog tam sim no suav hais tias yog cov khoom tseem ceeb siv rau SAG zeb liners. Muaj ntau qhov kev hloov pauv nrog cov ntsiab lus sib txawv ntawm cov pa roj carbon lossis chrome. Cov variations yuav muaj ib tug bearing ntawm qhov loj ntawm lub liner thiab nws seem thickness. Muaj kev txhim kho tsis tu ncua nyob rau hauv cheeb tsam no raws li qhov loj ntawm cov liners yog outstripping cov khoom muab los ntawm tus qauv siab chrome moly steels.

Nta

- Cov khoom siv ntawm SAG zeb liners yog qis C lossis siab C Cr-Mo Alloy steel, uas nyob ntawm qhov tshwj xeeb ua haujlwm ntawm SAG zeb;

- Chromium thiab molybdenum ob leeg ib leeg zuj zus ntxiv hardenability ntawm cov hlau tsis tshua muaj hlau. Cov teebmeem tseem ceeb ntawm kev sib koom ua ke, tseem tsis tau txhais tag nrho, tuaj yeem tshwm sim thaum Cr thiab Mo siv rau qhov chaw ntawm ib lub ntsiab lus;

- Metallographic qauv ntawm AS2074 L2C Steel yog Pearlitic;

- Chromium ua rau muaj kev tiv thaiv corrosion thiab oxidation, kub siab zog thiab abrasion kuj. Molybdenum pab tswj cov txheej txheem hardenability thiab ua kom kub siab tensile thiab creep zog. Cov qib no feem ntau raug kho kom sov rau cov khoom tshwj xeeb;

- Cov khoom siv hardness: 325-380 BHN

Thaum nws los txog rau chrome moly dawb hlau zeb liners, H&G Mill Liners tau tsom cov khoom siv no ntev. Peb chrome moly dawb hlau zeb liners ncua lub neej ntau dua li lwm cov foundries zeb liners.

Cov khoom cam khwb cia no suav hais tias yog qhov kawg tsim thiab siv rau hnub rau kev puas tsuaj hauv Milling. Nws yog feem ntau siv nyob rau hauv cov cement mills thiab qee qhov loj tshaj plaws Pob Zeb Mills nyob hauv lub ntiaj teb thiab qhov chaw ua haujlwm tsis tau zoo dua rau hnub tim.

Cov yam ntxwv

- 600 rau 700 BHN dawb hlau

- Cov pob zeb loj

- Malleable Iron: cam khwb cia li dawb hlau, ces malleabilised, los yog kub kho, impart ductility. Nws muaj tempered graphite nyob rau hauv ib tug-ferrite los yog pearlite

matrix - Feem ntau hauv cov cement mills

- Siv rau abrasion tsis kam