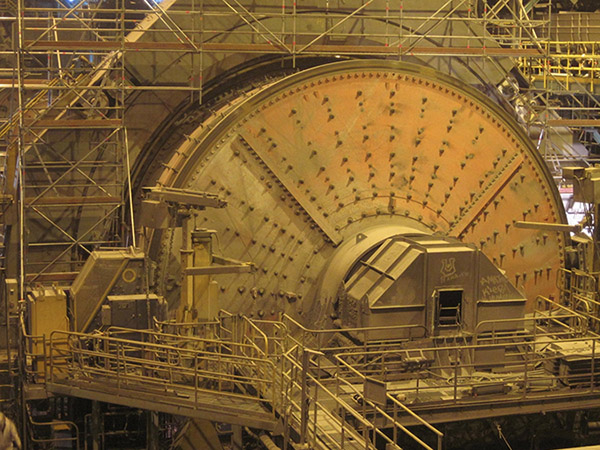

AG Mill Liner

Tsanangudzo Pfupi

Product Description

SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner kubva kuH&G inoshandisa Cr-Mo zvinhu (AS2074 Standard), SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner inopa hukuru hwepamusoro uye kuramba kupfeka mune ese semi-autogenous milling. applications.

Kusarudza chinhu chakakodzera chekushandisa chakakodzera ndicho chinangwa chedu , isu tiri kugara tichishanda pamwe chete nemutengi wedu kuti tiite izvi .The right material is on to:

1. Iyo mineral ground

2. Milling data data

3. Hukuru hwekukuya media dhayamita (mm)

4. Kukuya midhiya yekuzadza degree (%)

Kazhinji, Chinhu M1 chinoshandiswa kune yakakwira maitiro, P1 inoshandiswa kune yakaderera maitiro mamiriro. Ichachinja zvinoenderana nemamineral process yako.

Tsanangudzo Inowanikwa

|

Code |

Chemical Elements (%) SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 |

0.4-0.7 |

0.6-1.0 |

1.8-2.5 |

0.25-0.5 |

0-0.5 |

≤0.04 |

≤0.06 |

|

M1 |

0.3-0.45 |

0.4-0.7 |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 |

0-0.5 |

≤0.04 |

≤0.06 |

Zvenyama Zvivakwa & Microstructure

|

Code |

Kuoma (HB) |

Ak (J/cm2) |

Microstructure |

|

P1 |

325-375 |

≥50 |

P |

|

M1 |

350-400 |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Ongorora: Gadzirisa kemikari yemukati kana wedzera zvimwe alloying zvinhu SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner zvinoenderana nezvinodiwa nevatengi zviripo.

Product Package

● Pallet yeSimbi, Pallet Yemapuranga uye Bhokisi remapuranga

● Customized maererano inokosha packing zvinodiwa.

Kubatsira Kwedu

PaHG Casting, isu tinogadzira madhizaini, akagadzirirwa kunyanya kumutengi wese. Yedu SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner inogadzirwa kune yepamusoro indasitiri chiyero cheAutogenous Grinding (AG), Semi-Autogenous Kukuya (SAG), Yepuraimari / Sekondari uye kugayazve tsvimbo kana bhora magiyo. MGS Casting mill lining system yakagadzirwa nechikwata chedu chakadzidziswa, uye chakazvitsaurira pasirese chatora dunhu rese rekufunga. Kutsigira mutsara wedu wepamberi Mill Injiniya iboka hombe revanonyanya hunyanzvi dhizaini mainjiniya, makemikari ezvekushandisa, kugadzira uye logistics nyanzvi dzinoita basa rekupa basa rakasiyana.

Madhizaini echigayo akagadzirwa nechikwata chedu anotarisisa hupenyu hwesevhisi; kugaya & kugona kwesimba uye ore hunhu, pamwe ne costumer circuit constraints zvese kumusoro nekudzika kwechigayo.

HG Casting yakabudirira kushandisa ASTM 2074/L2B alloy simbi kugadzira AG/SAG mill liner. Pasi pechinhu ichi, hupenyu hwedu hwemagiyo hunogona kuvandudzwa. Vatengi vedu vekuAustralia vaive vaodha matani anopfuura zviuru gumi pagore zvezvigayo izvi.

Seyekutanga yekukandira, HG Casting zvakare ine SAG Semi-Autogenous Grinding Mill Liner uye AG Autogenous Grinding Mill Liner dhizaini. Kazhinji, nzvimbo yekusimudza uye kona, grate yakavhurika nzvimbo uye aperture size, uye pulp lifter dhizaini uye kugona kunofanirwa kutariswa. Imwe neimwe yeiyi misoro yakave nehuwandu hwakati wandei hwekutsvagisa, uye dzakawanda nyaya zvidzidzo zve evolutionary liner dhizaini dzakaburitswa. Zvichienderana neruzivo, madhizaini echigayo akafamba akananga kune yakavhurika goko rekusimudza volumetric kugona uye dhizaini dhizaini yekufambisa kukwirisa ese ari maviri-kupwanya maseketi mashandisirwo uye SAG chigayo. Kuburikidza kwechigayo kunokwidziridzwa nemagoko ekusimudza pakati pe2.5:1 uye 5.0:1. Iri reshiyo reshiyo rinotaurwa pasina chirevo chekona yechiso; Pane yakaenzana spacing-to-urefu reshiyo, zvikwiriso zvine hukuru hwemakona ekurerutsira zvichave nezvinetso zvishoma zvekurongedza pazvitsva asi zviine mapfekero epamusoro kupfuura ayo ane kukwirisa kumeso kona. Pulp lifter dhizaini inogona kuve yakakosha kufunga kune SAG mill, kunyanya kune hombe chigayo. Saizi dzese dzeguyo dzinowedzera, iyo inodiwa volumetric kugona kweanosimudza pulp inokura zvakaenzana kusvika kuhuyo.

Semi-autogenous grinding mill liner zvakare inonzi SAG mill liner, Autogenous grinding mill liner inonziwo AG mill liner. Kubva mugore ra2014, H&G Michina yanga yave imwe yevakuru veAG/SAG vanogadzira chigayo kubva kuChina. Hazvina mhosva kuti ndechipi chinhu chaunoda, manganese simbi kana Ni-yakaoma simbi kana Cr-Mo simbi kana alloy simbi; Hazvina mhosva kuti ndeupi rudzi rwechigayo chako chinoda. wave shape kana yakasimudzwa edge shape kana stepped shape; H&G Machina ndiyo sarudzo yako yekutanga.

Ndeipi Sarudza H&G Machinery's AG/SAG Mill Liners?

- Zvakapfuma ruzivo. H&G Michina inopa anopfuura zviuru gumi matani emhando dzakasiyana dzezvigayo.

- Zvinhu zvakasiyana-siyana. Tinopa zvinhu zvakasiyana-siyana kuti zvienderane nemamiriro akasiyana ekushanda. Zvakadai sesimbi yemanganese, Ni-hard simbi, Cr-Mo simbi, uye mamwe masimbi alloy.

- Zadzisa QC system. H&G Michina inopa yakakwana yemhando yekudzora sisitimu uye marekodhi. Unogona kutarisa magwaro ese uye marekodhi paunotishanyira kana isu tinokutumira kwauri.

- OEM sevhisi. H&G Michina inogona kugadzira liner dzako nedhizaini yako kana dhizaini yedu yeinjiniya.

AG SAG Mill Liner Basa

Semi-autogenous grinding uye autogenous grinding ihuyo hupfu ine silinda yakakura dhayamita uye inotenderera inotenderera. Izvo zvinhu zvinodyiswa muguyo kuburikidza neine mhango jenari pamagumo ekudyisa. Pasi pekubatana kwemidziyo, iyo yakapwanyika kune imwe fineness inopfuura nekubuda Iyo hollow magazine kumagumo inoburitswa kunze kwemuchina. Iyo liner chikamu chakakosha chemuchina wekukuya.

- Iyo yekusimudza liner inosimudza zvinhu kusvika kune imwe nzvimbo yakakwirira, kukanganisa kwekusununguka kwekusununguka, uye kupesana kwekuita pakati pekukakavadzana pakati pezvinhu, kuitira kuti zvinhu zviputswe uye zvigadzikane pasi.

- Chimiro chekupedzisira chivharo chekuvhara bhodhi chinenge chakakosha. Izvo zvinhu zvakawanda zvinowedzerwa kuburikidza nechiteshi chekudya. Zvidimbu zvidiki zvezvinhu zvinowira zvakafanana pazasi pepakati pehumburumbira pamwe nepamusoro peiyo wave lining zvobva zvapararira mativi ese, ukuwo zvidimbu zvakakura zvezvinhu zvine simba guru rekinetic. : Iyo projectile point inogara yakananga kudivi rekure, asi chikamu chayo chinozobonderana nemativi maviri ewave lining. Pamusana pekupikisa kwemaitiro emagetsi emagetsi, zvinogona kudzivirira kuti zvinhu zvirege "kuparadzaniswa" muaxial yakakura uye zvidimbu zviduku, kuitira kuti zvidimbu zvakakura zvezvinhu zvigove zvakaenzana. Iyo yakakasharara zvinhu yakadzoka kubva kumagumo ekuburitsa parutivi rwezasi, senge ichangobva kuwedzerwa zvinhu block, yakaenzana inowira pakati pepasi pe silinda uye yobva yapararira kumativi ese. Izvo zvinhu zvakakura uye zvakanaka-zviyo zvinofamba zvakatarisana pamwe chete neaxial kutungamira pazasi kweChinese yakareruka, saka vane mhedzisiro yekukuya.

- Ose ari maviri anosimudza T-yakaita lining plate uye wave plate ine basa rekuchatisa block. Nekutenderera kweguyo, nzvimbo ye block inowedzera, uye simba rekumanikidza rinokurumidza kunyangarika uye rinova kushushikana kana "arched" bhiriji richikwira kumusoro uye rinodonha kuitira kuti kushushikana kwepakarepo kunokonzerwa nekuenderera kunoenderana kudzoreredza kuchaita kuti block mamonomeri anoparadzaniswa, zvichikonzera kugaya.

AG/SAG Mill Liner Material Sarudzo

Yakasiyana yakapwanyika zvinhu, akasiyana ekushanda mamiriro anoda akasiyana zvinhu liner kuti aenderane. Kuti zvizadzise zvinodiwa nemutengi AG kana SAG chigayo liner, zvinhu zvemill liner zvakakura zvakanyanya high manganese simbi, high alloy white cast iron, high carbon chromium-molybdenum steel, medium carbon chromium-molybdenum steel, etc. The matrix chimiro chinosanganisira austenite, martensite, bainite, uye pearlite.

H&G Michina inopa zvinotevera zvinhu kukanda yako AG kana SAG mill liner:

High Manganese Steel

Yakakwira manganese simbi isimbi yechinyakare yeabrasion resistance uye mill lining. Inoshandiswa zvakanyanya mumamiriro akasiyana-siyana ekupfeka nekuda kwebasa rayo rinoshamisa rekuomesa. Chikonzero nei iyo yakakwira manganese simbi lining plate ine hupenyu hurefu hwesevhisi ndeyekuti hombe yebhora ine speed inononoka uye simba guru rekuita pakati pebhora rekukuya nesimbi. Basa rekuomesera mhedzisiro yesimbi yakakwira manganese yakakosha, uye hama iri pakati pe ore uye lining plate Iyo yekumhanyisa idiki. Nekudaro, yakakwira manganese simbi inewo kushaya simba kunouraya, ndiko kuti, kana paine kukanganisa kukuru, nekuda kwesimba rayo regoho rakaderera, zviri nyore kuita rheology, zvichikonzera deformation yakakura ye liner, yakaoma kuparadzanisa liner, uye bhaudhi richavhunwa mumatambudziko makuru.

Alloy white cast iron

Iyo inomiririra zvinhu zvealloy white cast iron yakakwira chromium cast iron, uye iyo Cr yemukati inowanzova yakakura kupfuura 12%. Nekuti ine yakaparadzana tsvimbo-yakanyanya-kuoma M7C3 mhando carbides, inoratidza yakakwirira kuomarara uye zviri nani kukanganisa kuomarara (ichienzaniswa nechena simbi yakakandwa), uye yave ichionekwa zvakanyanya sechizvarwa chitsva chezvigadzirwa zvisingapfeke, uye inoshandiswa kune liner yeball mill. Zvisineyi, kuoma kwesimbi yakakwira chromium kuchiri kwakadzikira (kazhinji 5 ~ 7 J/cm2), saka simbi yakakwira chromium inongokodzera kucherwa kwemaraini madiki-madiki uye mareji mahombe mumaguyo esimende. Zvigayo zvidiki-dhayamita zvakanyorova (madhiyamita ari pasi pe2.5 m) haakodzere zvigayo zvakakura-dhayamita zvine simba guru rekuita, kunyanya chigayo chikuru cheSAG.

Alloy Steel

Alloy simbi seyakapfeka-inodzivirira zvinhu yakawanawo mhedzisiro yakanaka mumashandisirwo anoshanda. Chikonzero chikuru ndechekuti iyo kabhoni yemukati yealloy simbi uye mhando uye zviri mukati meiyo alloy zvinhu zvinogona kusiyanisa mukati mehukuru hukuru. Nematanho akasiyana ekurapa kupisa, Chimiro uye zvimiro zvesimbi yealloy zvinogona kugadziridzwa mukati mehombe yakakura kuti iwane zviri nani yakazara ma mechanical zvivakwa uye kusangana nezvinodiwa zveakasiyana mamiriro ekushanda. Tsvagiridzo nekuita zvakaratidza kuti simbi yealloy yakakodzera sechigayo chemichina mikuru yekuzvikuya nemichina yekuzvigaya, sekuratidzwa patafura:

| Hupenyu hwehukama hweAlloy Liner Yakashandiswa muAG Mill | ||||||

| Alloy Steel Species | Bhora Media | Diameter 11.0m AG Mill Shell liner |

Diameter 8.2m AG Mill Shell liner |

Diameter 9.8m AG Mill Shell liner |

Diameter 9.8m AG Mill End liner |

Diameter 14.4m AG Mill End liner |

| Austenitic 12% Mn simbi | 0.64 | / | / | / | / | / |

| Pearlite 0.8%C Cr-Mo chiwanikwa | 0.7 | / | 0.46 | 0.48 | / | 0.54 |

| Martensite 0.4%C Cr-Mo alloy | 0.77 | 0.63 | 0.67 | / | 0.73 | 0.81 |

| Martensite 1.0% Cr-Mo chiwanikwa | 0.85 | / | / | / | / | 0.94 |

| Martensite 2% Cr-4% Ni iron alloy | 0.83 | 0.67 | / | / | / | / |

| Martensite 8% Cr-4% Ni iron alloy | / | 0.79 | / | / | / | / |

| Chromium-molybdenum simbi yakakandwa | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

Zvinogona kuonekwa kuti martensitic Cr-Mo alloy simbi lining plate ine yakanaka yekushandisa mhedzisiro mumuchina wekuzvigaya, uchiteverwa nepearlite Cr-Mo alloy simbi lining plate. Pearlite Cr-Mo alloy simbi lining yakashandiswa zvakanyanya mumasemi-otomatiki zvigayo. Kunyangwe kusapfeka kwayo kwakashata zvishoma pane martensitic Cr-Mo alloy simbi, kuoma kwayo kusimba kwakakwira kupfuura martensitic Cr -Mo alloy simbi, saka yakakodzera muchina muhombe-wega wokugayo une simba rakakura.

AG/SAG Mill Liners Mhando

Zvichienderana nenzvimbo yekushandiswa, inogona kukamurwa kuva:

- Kusimudza Liner

- End Liner

- Shell Liner

AG/SAG Mill Liners Maumbirwo

Chimiro che AG/SAG mill liners chinosanganisira:

- Flat liner. Kune silo yekukuya yakanaka, kureba kwekukwira kwemuviri wekukuya kunoenderana neiyo static friction coefficient pakati pemarata ekuya.

- Bead liner. Inoshandiswa mubhini rekutanga, inogona kuita kuti muviri wekukuya ukwire kumusoro uye uve nesimba rakakura rekuita.

- Convex ribbed liner. Zvakafanana nebead liner.

- Wave liner. Inokodzera baseball kugaya.

- Ladder liner. Inokodzera kupwanya silo uye inoshandiswa zvakanyanya.

- Hemispherical liner. Inokodzera kupwanya silo.

AG/SAG Mill Liners Kuiswa

Kugadzirira Basa

- Gadzirira zvese zvinodiwa kutsiva mill liner.

- Tarisa chimiro uye ukuru hwemaplateti ese, bvisa mapapiro ebvudzi, kukanda slag, nezvimwewo;

- Gadzirira kutsiva mabhaudhi anodiwa, nzungu uye washer uye zvimwe zvinhu;

- Nyatsotarisa kana midziyo yekusimudza, midziyo uye rigging zvakachengeteka uye zvakavimbika.

- Gadzirira 36V kuchengetedza magetsi ekuvhenekesa kwekuvaka muchubhu;

- Chigayo chisati chamiswa, panofanira kuva nemaminerari akakwana mubhodhoro akakodzera kupinda nekubuda kwemutsara usati wamira.

- Vese vashandi vekuvaka vanofanirwa kupfeka zvekudzivirira zvevashandi zvinosanganisira heti dzakaoma, masiki, uye shangu dzisina kutsvedza vasati vapinda munzvimbo.

Installation Matanho

- Bvisa trolley yekudyisa uye simudza hovha yekugamuchira;

- Bvisa mabhaudhi ekugadzirisa e liner chidimbu nechidimbu kuchengetedza uye kuchenesa ese screw maburi. Usabvisa zvinopfuura 3 seti ye liner panguva imwe;

- Simudzira kunze akabviswa AG chigayo liners rimwe nerimwe nekushandisa kutyaira, uye ipapo kurembera lining board kuti kutsiviwa kupinda chubhu;

- Pasi pekutungamira kwemutungamiriri wekusimudza, shandisa mota kupfeka tambo yewaya kuburikidza nemaburi ebhaudhi ecylinder, dhonza bhodhi rekuisa kune inodiwa yekumisikidza chinzvimbo, uye ipapo shandisa crowbar kutwasanudza screw uye nati. Zadza maburi maviri escuru ebhodhi relining achichinjana nemhete dzehemp (zvisingasviki mashanu muboka rega rega), isa inovuza inomisa rabha ring uye flat washer uye simbisa nati;

- Pakuisa chigayo, madhipoziti nemarara panzvimbo yekuisa anofanira kucheneswa;

- Kana zvikaonekwa kuti iyo yekuburitsa giredhi yekumisikidza saiti yakasakara zvakanyanya, iyo yekuburitsa dhiza inofanira kutsiviwa isati yatsiviwa gireti;

- Isa yekudzoreredza feed trolley uye mine funnel.

Matanho ekuchengetedza uye zvinodiwa zvehunyanzvi

1. Usati wasimudza mabasa, midziyo yose inofanira kunyatsoongororwa zvakanyatsoenderana nemitemo yakakodzera. Iyo tambo inofanirwa kusimba pakusimudza zvinhu, uye vanofamba netsoka vanofanirwa kuyeuchidzwa kuti vadzivise. Murairo unofanira kugadza munhu akakosha kuti aite basa;

2. Vashandi vekuvaka vanofanira kunyatsotevedzera mirairo yekuchengetedzwa kwehunyanzvi hwekuita, kubvisa mirairo isiri pamutemo uye kushanda zvisiri pamutemo, kupfeka zvakasiyana-siyana zvekuchengetedza basa, uye kurambidza kunwa nekunwa;

3. Zvigayo zvigayo zvinofanira kugadziriswa zvakasimba pasina kusununguka. Mabhaudhi ese anofanira kusimbiswa panzvimbo. Hapachave nekudonha kwemvura mumipata yakatenderedza sikuruu mushure mekutyaira;

4. Tora kuchengetedzwa kwakanaka kutenderedza saiti kudzivirira kudonha. Kushanda kwepamusoro-soro kunofanirwa kusunga mabhandi ezvigaro maererano nemitemo yakakodzera, kudzivirira panguva imwe chete kumusoro uye pasi kushanda;

5. Apo cylinder inoda kufambiswa maererano nekutsiviwa kweplate yekugadzira, kutanga kune zvose, zvakakosha kusimbisa kana kune vanhu vari muvhareta uye kumativi ose pamberi pekuti cylinder inogona kuendeswa. Iyo hollow shaft yekuzora pombi yemafuta inofanirwa kutangwa isati yapwanya;

6. Paunenge uchishanda muguyo, unofanira kutanga wacheka simba remidziyo yakakodzera uye urembera chiratidzo chekunyevera. Kuvhenekera muchubhu kunofanirwa kuve nechokwadi chekuvhara tambo yakanaka uye kushandisa yakachengeteka voltage;

7. Midziyo yekuvaka yakaita sezvipfuramabwe, machira, uye makwara zvichamiswa kana zvaonekwa kuti zvakuvadzwa kana kuti zvisina.