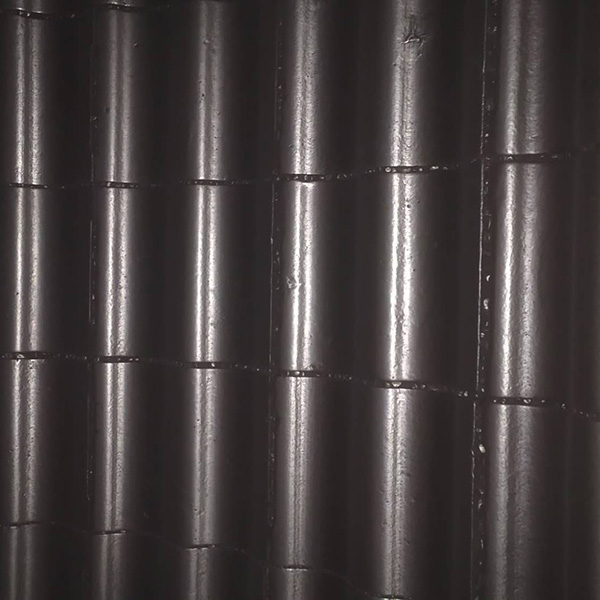

26%Cr 28%Cr High Cr Grinding Mill Liner

Tlhaloso e Khutšoanyane:

Tlhaloso ea Sehlahisoa

White Iron Ball Mill Liner ka kakaretso e bolela tšepe e tšoeu ea alloy e nang le chromium ho 12% ~ 26%, carbon content ho 2.0% ~ 3.6%. White Iron Ball Mill Liner likarolo tse ikhethang ke hore mofuta oa M7C3 eutectic carbide micro hardness ke HV1300 ~ 1800. White Iron Ball Mill Liner's eutectic carbide e ajoa motheong, martensite(mokhatlo o thata ka ho fetisisa oa tšepe oa tšepe), marang-rang a sa khaotseng le karohano, e fokotsang karohano ea phello ea matrix. Ka lebaka leo, chromium Ball Mill Liner e phahameng e na le matla a phahameng, ho tiea ho matla le likarolo tse ntle tsa ho hanyetsa, tse sebelisoang haholo indastering ea Merafo, Samente le matla.

White Iron Ball Mill Liner e khothaletsoa hore e sebelisoe maemong a tlase a ts'ebetso joalo ka:

1. lebanta conveyor laner bakeng sa indasteri ea Merafo.

2. Semela sa samente Ball Mill.

3. Indasteri ea lik'hemik'hale Ball Mill.

Lintho tsa Lik'hemik'hale

|

Lebitso |

Lintho tsa Lik'hemik'hale (%) |

|||||||

|

C |

Si |

Mong |

Kr |

Mo |

Cu |

P |

S |

|

|

High Cr Ball Mill Liner Cr26 |

2.5-3.3 |

0-0.8 |

≤2.0 |

23--28 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

|

High Cr Ball Mill Liner Cr15 |

2.3-3.3 |

0-0.8 |

≤2.0 |

14--18 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

Thepa ea 'Mele & Microstructure

|

Lebitso |

HRC |

Ak(J/cm2) |

Microstructure |

|

High Cr Ball Mill Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C- Carbide A-Austenite |

|||

Tlhokomeliso: Fetola litaba tsa lik'hemik'hale kapa u kenye likarolo tse ling tsa motsoako oa Ball Mill Liner ho latela litlhoko tsa bareki li fumaneha.

Sephutheloana sa Sehlahisoa

● Paletla ea Tšepe, Paletla ea Lehong le Lebokose la Lepolanka

● Customized ho ea ka tlhokahalo e khethehileng ea ho paka.

Kopo

White Iron Ball Mill Liner ea rona e sebelisoa haholo sethaleng sa ho sila bakeng sa indasteri ea merafo, indasteri ea samente, setsi sa motlakase oa mocheso, indasteri ea ho etsa pampiri le ea lik'hemik'hale joalo-joalo.

Leloala la bolo ke mofuta oa grinder e sebelisetsoang ho sila, ho tsoaka 'me ka linako tse ling bakeng sa ho kopanya lisebelisoa tse sebelisoang mekhoeng ea ho roala liminerale, lipente, pyrotechnics, ceramics le selective laser sintering. E sebetsa ka molao-motheo oa tšusumetso le ho fokotseha: ho fokotsa boholo ho etsoa ka tšusumetso ha libolo li theoha ho tloha haufi le holimo ho khetla.

Leloala le na le khetla e sekoti ea cylindrical e potolohang ho potoloha axis ea eona. Axis ea khetla e ka ba e rapameng kapa ka lehlakoreng le lenyenyane ho ea ho tse rapameng. E tletse libolo ka mokhoa o itseng. Mecha ea ho sila ke libolo, tse ka 'nang tsa etsoa ka tšepe (tšepe ea chrome), tšepe e sa hloekang, ceramic kapa rabara. Sebaka se ka hare sa khetla ea cylindrical hangata se na le lisebelisoa tse thibelang ho senya tse kang tšepe ea manganese kapa lesela la rabara. Ho se sebetse ho hoholo ho etsahala ka lifemeng tse nang le rabara. Bolelele ba leloala le batla le lekana le bophara ba lona.

Ha ho tluoa ho li-liner tsa tšepe tse tšoeu tsa chrome moly, H&G Mill Liners e ne e tsepamisitse thepa ena nako e telele. Lisebelisoa tsa rona tsa chrome moly white iron liner li phela ho feta lifensetere tse ling.

Thepa ena e nkoa e le eona e tsoetseng pele le e sebelisoang ho fihlela joale bakeng sa ho hanyetsa abrasion ho Milling. E atisa ho sebelisoa ka licheleteng tsa samente le tse ling tsa Ball Mills tse kholo ka ho fetisisa lefatšeng le moo ts'ebetso e sa kang ea ntlafatsoa ho fihlela joale.

Likarolo

- 600 ho 700 BHN tšepe e tšoeu

- Mehala e meholo ea bolo

- Iron e Malleable: e entsoe joalo ka tšepe e tšoeu, ebe ea senyeha, kapa ea phekoloa mocheso, ho fana ka ductility. E na le graphite e futhumetseng ka har'a

matrix ea a-ferrite kapa pearlite - E tloahelehileng ka lifemeng tsa samente

- E sebelisoa bakeng sa ho hanyetsa abrasion

Ha ho tluoa ho li-liner tsa Ni-hard iron mill, H&G Mill Liners e ne e tsepamisitse maikutlo ho hlahisetsa bareki ba rona thepa ena. Li-liner tsa rona tsa Ni-hard iron liner li phela ho feta liner tse ling.

Ni-Hard Cast Iron e tsebahala haholo ka ho tšoarella ha eona le boleng ba eona. Lisebelisoa tse entsoeng ka Ni-Hard ha li na matla ebile li lelefatsa bophelo ha li bapisoa le tšepe e 'ngoe kapa tšepe e bonolo. Likahare tsa Nickel li eketseha ka boholo ba karolo kapa nako ea ho pholile 'me li thibela phetoho ea pearlitic ea tšepe e entsoeng ka tšepe.

Thepa ena Tšebeliso ea thepa ea mofuta ona ka kakaretso e qalile ka Rod Mills le Ball Mills, moo litšusumetso li neng li nkuoa li le tlase ka ho lekaneng hore moaparo ona o brittle empa o sa khone ho sebetsa hantle. Leha ho le joalo, hona joale e nkoa e sa sebetse ho latela tšebeliso ea litšepe tse phahameng tsa chrome le tšepe ea moly white ea chrome.

Likaroloana

- Chromium hangata e kenyelelitsoe pakeng tsa 1.4-4% ho netefatsa hore khase ea carbon e tiisa ho carbide, eseng graphite. (E hanyetsana le phello ea graphitizing ea Ni);

- Ho hanyetsa abrasion (hangata thepa e lakatsehang ea thepa ena) ho eketseha ka carbon content, empa boima bo fokotseha;

- E na le matrix a martensite, a nang le nickel alloyed ka 3-5% e le ho hatella phetoho ea austenite ho pearlite;

- Ho hanyetsa abrasion (hangata thepa e lakatsehang ea thepa ena) e eketseha ka carbon content, empa boima bo fokotseha;

- Mefuta e fapaneng ea limaraka tsa sehlopha sa I ke thaepa A abrasion resistance; class I type B toughness;

- Likopo: Ka lebaka la litšenyehelo tse tlase, tse sebelisoang haholo-holo lits'ebetsong tsa merafo e le li-mill liner le libolo tsa ho sila;

- Boima ba lintho tse bonahalang: 550 BHN

Ha ho tluoa tabeng ea li-liner tsa tšepe tse tlase tsa carbon chrome moly steel, H&G Mill Liners e ne e tsepamisitse maikutlo ho hlahisetsa bareki ba rona thepa ena. Lisebelisoa tsa rona tse tlase tsa carbon chrome moly steel mill liner li qeta bophelo ho feta liner tse ling tsa foundries.

Thepa ena e boetse e bitsoa tšepe ea AS2074 L2B. Ts'epe ena e atisa ho sebelisoa bakeng sa li-mill liners (AG, SAG le Ball) pele ho ts'ebetso ho ea ho litšepe tse phahameng tsa carbon content. E na le litšobotsi tse ntle tsa ho apara tse nang le ts'ebetso e itseng ea ho hanyetsa, hangata e sebelisoang hona joale bakeng sa li-grates tse ntšang metsi moo ho hlokahalang hore ho be bonolo ho hanyetsa ha ho bapisoa le litšepe tse phahameng tsa carbon chrome moly kapa bakeng sa li-liner tse tšesaane.

Likaroloana:

- E sebelisoa bakeng sa AG/SAG le mekotla ea bolo;

- Litšobotsi tse ntle tsa ho apara le ho hanyetsa ho itseng;

- Sebopeho sa Metallographic sa AS2074 L2B Steel ke Pearlitic;

- E ntle bakeng sa li-grate tsa ho lahla;

- Ho thatafala ha AS2074 L2B ke HB310-HB380.

Ha ho tluoa tabeng ea li-liner tsa tšepe tse phahameng tsa carbon chrome moly steel, H&G Mill Liners e ne e tsepamisitse maikutlo ho hlahisetsa bareki ba rona thepa ena. Li-liner tsa rona tse phahameng tsa carbon chrome moly steel mill li phela nako e telele ho feta lifensetere tse ling.

Boitsebiso bona bo boetse bo bitsoa tšepe ea AS2074 L2C. Hona joale tšepe ena e nkoa e le thepa e ka sehloohong e sebelisoang bakeng sa li-liner tsa leloala tsa SAG. Ho na le mefuta e mengata e fapaneng e nang le litaba tse fapaneng tsa khabone kapa tsa chrome. Mefuta e fapaneng e atisa ho ba le phello ho boholo ba liner le botenya ba karolo ea eona. Ho na le tsoelo-pele e tsoelang pele ka har'a sebaka sena kaha boholo ba li-liner bo ntse bo feta thepa e fanoeng ke litšepe tse phahameng tsa chrome moly.

Likaroloana

- Thepa ea li-liner tsa SAG ke tšepe e tlase ea C kapa e phahameng ea Cr-Mo Alloy, e itšetlehileng ka boemo bo itseng ba ho sebetsa ba leloala la SAG;

- Chromium le molybdenum ka bobeli li eketsa ho thatafala ha tšepe ea alloy e tlase. Liphello tsa bohlokoa tsa synergistic, tse e-s'o hlalosoe ka botlalo, li ka boela tsa etsahala ha Cr le Mo li sebelisoa sebakeng sa likarolo tse le 'ngoe;

- Sebopeho sa Metallographic sa AS2074 L2C Steel ke Pearlitic;

- Chromium e tlisa khanyetso ho corrosion le oxidation, matla a mocheso o phahameng le ho hanyetsa abrasion. Molybdenum e thusa ho boloka ho thatafala ho itseng le ho eketsa mocheso o phahameng oa ho tsitsa le matla a ho thella. Limaraka tsena ka kakaretso li tšeloa mocheso ho ea ho thepa e boletsoeng;

- Boima ba lintho tse bonahalang: 325 ho 380 BHN

Litlhoko tsa ho kenya Ball Mill Liner

- Kamora hore leloala le kenngoe, poleiti ea ho qetela le sekoaelo sa cylinder li lokela ho tlatsoa ka sekhahla sa matla a hatellang sa 43.5MPa seretse sa samente.

- Liboutu tse lokisang moeli oa ho qetela li ke ke tsa lumella seretse sa samente hore se lekane, empa se tla khona ho potoloha kapa ho kena le ho tsoa.

- Leloala la leloala ka kakaretso le lebile ka lehlakoreng le leng, u tlameha ho le ela hloko nakong ea ho kenya, u se ke oa furalla.

- Bolelele ba li-arc tsa li-slits tsohle tse pota-potileng ha boa lokela ho feta 310mm, 'me e feteletseng e tla kenngoa ka lipoleiti tsa tšepe ho e arola.

- Lekhalo pakeng tsa li-liner tse haufi ha le fete 3 ~ 9mm.

- Interlayer e lokela ho behoa ho ea ka litlhoko tsa moralo pakeng tsa liner le bokaholimo ba ka hare ba silinda. Haeba ho sa hlokahale, seretse sa samente se nang le matla a ho hatella a 42.5MPa se ka tlatsoa pakeng tsa tse peli. Ka mor'a hore seretse sa samente se behoe, tiisa liboutu tsa liner hape.

- Ha u kenya lesela le nang le liphahlo tsa rabara, bula letlapa la rabara e koetsoeng libeke tse 3 ho isa ho tse 4 pele u kenya ho e lumella ho otlolla ka bolokolohi; ha u sebelisa letlapa la rabara, lehlakoreng le lelelele la letlapa la rabara le lokela ho latela tataiso ea axial ea silinda, Lehlakoreng le lekhutšoane le latela selikalikoe sa silindara.

- Sheba ka hloko masoba a liner bolt le geometry ea liboutu tsa liner, 'me u hloekise ka hloko masoba a flash, li-burrs le li-protrusions holim'a masoba a liner bolt le liboutu tsa liner e le hore liboutu li khone ho kenella ka bolokolohi sebakeng se hlokahalang.

- Sehlopha se feletseng sa liboutu tsa liner li lokela ho ba le liboutu tse benyang, li-washer tsa lerōle, li-washer tse bataletseng, li-washer tsa selemo le linate; e le ho thibela ho tsoa ha molora, ha ua lokela ho lebala ho sebelisa liphahlo tsa lerōle nakong ea tšebeliso.

- Ha o tiisa liboutu tsa lesela, ho lokela ho sebelisoa sekontiri sa torque bakeng sa ts'ebetso. Li-bolts tsa linepe tsa litlhaloso tse fapaneng li lokela ho tiisoa ho latela litlhoko tse lumellanang tsa torque.