Samente Sila Ball Mill Sebelisa Ho Sila Media Ball Lahlela tšepe sila Ball Casting tšepe Ball

Tlhaloso e Khutšoanyane:

Tlhaloso ea Sehlahisoa

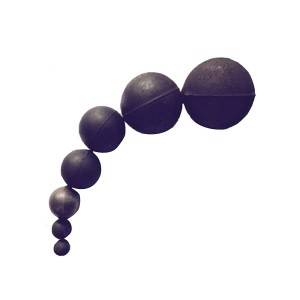

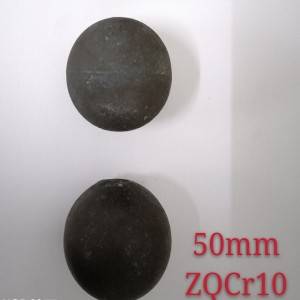

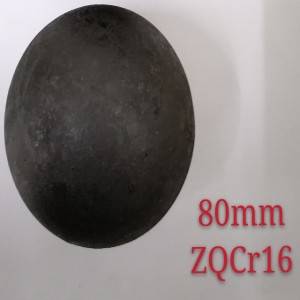

Samente Grinding Ball boholo ba ho tloha 12-125 limilimithara, 45-65 HRC, 1-23 % Cr. dikahare.

Cement Grinding Cylpeb ea boholo bo hlokahalang 45-65 HRC, 1-23 % Cr. dikahare.

Grinding Media Grinding Ball e hlahisoa ka mela e felletseng ea Auto, e netefalitsoeng tlasa maemo a machaba a boleng.

Re netefatsa hore Ball ea rona ea ho sila ea Cement e na le sekhahla se tlase sa ho robeha, tšebeliso e tlase ea tšebeliso, le maemo a ho tsamaisa kapele.

Tlhaloso e Fumaneha

|

Lebitso |

Chemical Element (%) |

|||||||

|

C |

Si |

Mong |

Kr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Grinding Ball le Grinding Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 |

10-23 |

0-3.0 |

0-1.2 |

≤0.06 |

≤0.06 |

|

Ball e silang ea Low-Cr Alloyed le Cylpeb e silang |

1.8-3.6 |

≤1.5 |

0.3-1.5 |

1-6 |

0-1.0 |

0-0.8 |

≤0.06 |

≤0.06 |

Thepa ea 'Mele & Microstructure

| Lebitso |

Ho thatafala (HRC) |

Tšusumetso Ak (J/cm 2) |

Microstructure |

Linako tsa Libolo tse oang |

||

|

High-Cr Alloyed Grinding Ball le Grinding Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

Ball e silang ea Low-Cr Alloyed le Cylpeb e silang |

≥45 |

≥2.5 |

P+C |

≤Φ80 |

≥12000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Tlhaloso ea Ball ea ho Sila

|

Boholo (mm) |

Boima (kg) |

Bongata (pc/t) |

|

Boholo (mm) |

Boima (kg) |

Bongata (pc/t) |

|

Φ17 |

0.027 |

37037 |

Φ70 |

1.37 |

729 |

|

|

Φ20 |

0.032 |

31250 |

Φ80 |

2.05 |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 |

345 |

|

|

Φ40 |

0.25 |

3891 |

Φ100 |

4.00 |

250 |

|

|

Φ50 |

0.50 |

2000 |

Φ110 |

5.30 |

188 |

|

|

Φ60 |

0.86 |

1153 |

Φ120 |

6.80 |

147 |

Sephutheloana sa Sehlahisoa

● Nylon Ton Mokotla: Boima ba 'mele: 1000 kgs; Boima ba 'mele: 1002kgs

● Drum ea tšepe: Boima ba 'mele: 850 - 900 kgs; Boima ba 'mele: 865 - 915 lik'hilograma

Kopo

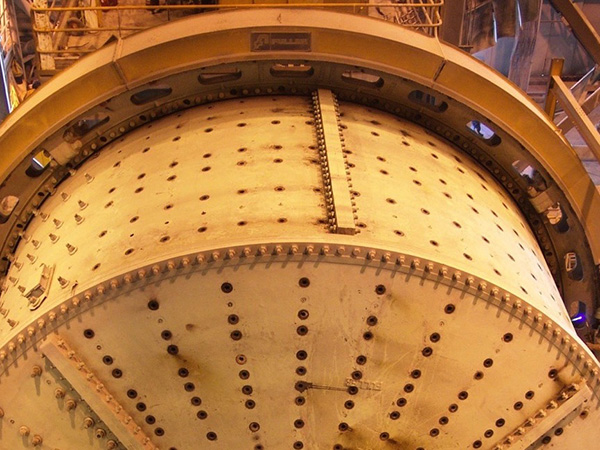

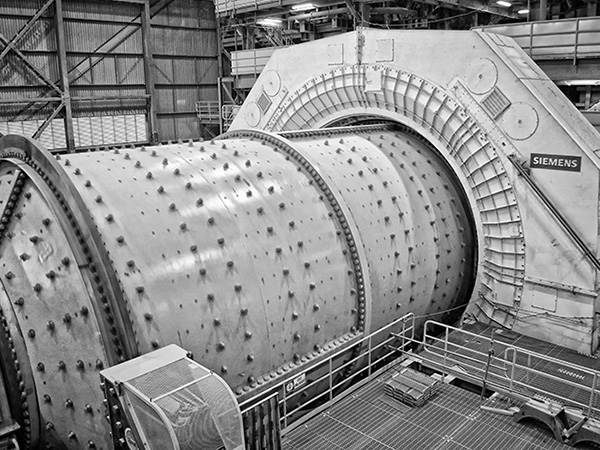

Libolo tse silang li sebelisetsoa ho sila kapa ho kopanya thepa. Bolo e silang e sebetsa ka molao-motheo oa tšusumetso le ho fokotseha. Libolo tsa pejana li ne li entsoe ka tšepe, ceramic kapa rabara. Matsatsing ana ke tsa mahlale haholo 'me Magotteaux e li etsa ka li-alloys tse loketseng mesebetsi eo ba tlamehang ho e etsa ho etsa hore li senyehe le ho sebetsa hantle haholo tlhahisong. Re tla u fa keletso ea hore na ke libolo life tse loketseng litlhoko tsa hau tse khethehileng.

Khetho ea ho sila bolo ea mecha ea phatlalatso e tla lula e itšetlehile ka thepa e lokelang ho ba fatše. U hloka ho lekola granulometry ea eona le mokhoa oa ho sila. U boetse u hloka ho sheba bohlokoa bo lekanyelitsoeng ba mekhoa ea ho apara ts'ebetsong.

High-Chrome ho sila bolo ea mecha ea phatlalatso e kopanyang sebopeho sa martensitic le li-carbides tse thata tsa chrome, Sena se fana ka khanyetso e ntle ka ho fetisisa ea ho roala khahlanong le ho senya le ho senya mefuta eohle. Boitseanape ba HG's bo ba thusa ho khetha motsoako o lekanang kopo ea hau hantle le ho fokotsa litšenyehelo. High-Chrome grinding bolo ea mecha ea phatlalatso e na le ts'ebetso e phahameng 'me e etsa hore maemo a tsitsitseng a be teng ka lebaka la sekhahla sa eona se tlaase. Bakeng sa motsoako o mong le o mong o khethehileng ho na le boima bo sa feleng ba bolo eohle ea ho sila mecha ea litaba. Sena se baka tšusumetso e ntle ts'ebetsong ea ho theoha. high-Chrome ho sila mecha ea phatlalatso ea ho sila bolo ke a loketse bakeng sa ka bobeli metsi le omileng ore ditshebediso tsa ka ho sila bolo le Mills sila tora.