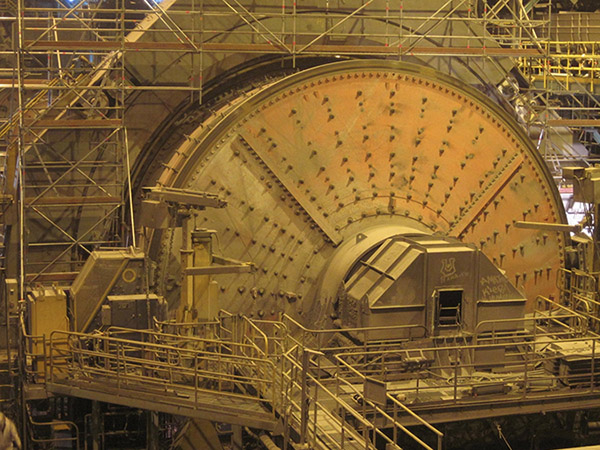

Citic SAG le AG Mill Liner

Tlhaloso e Khutšoanyane:

Tlhaloso ea Sehlahisoa

SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner tse tsoang ho H&G li sebelisa thepa ea Cr-Mo (AS2074 Standard), SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner e fana ka tšusumetso e matla le ho hanyetsa ho se sebetse ho felloang ha matla ho li-semi-autogenous milling. lits'ebetso.

Ho khetha thepa e nepahetseng bakeng sa ts'ebeliso e nepahetseng ke sepheo sa rona , re lula re sebetsa 'moho le moreki oa rona ho fihlela sena .Thepa e nepahetseng ke ho:

1. Sebaka sa liminerale

2. Ho tlatsa lintlha tsa data

3. Bophahamo ba media ba ho sila (mm)

4. Tekanyo ea ho tlatsa mecha ea litaba (%)

Ka kakaretso, Ntho ea M1 e sebelisetsoang boemo bo nang le tšusumetso e phahameng, P1 e sebelisetsoang boemo bo tlase ba tšusumetso. E tla fetoha ho latela ts'ebetso ea hau ea liminerale.

Tlhaloso e Fumaneha

|

Khoutu |

Chemical Elements (%) SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner |

|||||||

|

C |

Si |

Mong |

Kr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 |

0.4-0.7 |

0.6-1.0 |

1.8-2,5 |

0.25-0.5 |

0-0.5 |

≤0.04 |

≤0.06 |

|

M1 |

0.3-0.45 |

0.4-0.7 |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 |

0-0.5 |

≤0.04 |

≤0.06 |

Thepa ea 'Mele & Microstructure

|

Khoutu |

Ho thatafala (HB) |

Ak (J/cm2) |

Microstructure |

|

P1 |

325-375 |

≥50 |

P |

|

M1 |

350-400 |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Tlhokomeliso: Fetola litaba tsa lik'hemik'hale kapa u kenye lisebelisoa tse ling tsa motsoako oa SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner ho latela litlhoko tsa bareki li fumaneha.

Sephutheloana sa Sehlahisoa

● Paletla ea Tšepe, Paletla ea Lehong le Lebokose la Lepolanka

● Customized ho ea ka tlhokahalo e khethehileng ea ho paka.

Molemo oa Rōna

Ho HG Casting, re etsa meralo e ncha, e etselitsoeng moreki e mong le e mong. SAG Semi- Autogenous SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner li entsoe ho latela maemo a holimo ka ho fetisisa a indasteri bakeng sa Autogenous Grinding(AG), Semi-Autogenous Grinding(SAG), Primary / Secondary le ho sila hape lithupa kapa liloala tsa bolo. Sistimi ea liline ea MGS Casting e entsoeng ke sehlopha sa rona se koetlisitsoeng haholo, le se inehetseng lefatšeng ka bophara se nahanela potoloho ea hau eohle. E ts'ehetsang karolo ea rona ea pele ea Mill Engineers ke sehlopha se seholo sa baenjiniere ba meralo ba khethehileng haholo, litsebi tsa k'hemistri ea lintho tse bonahalang, litsebi tsa tlhahiso le tsa thepa tse ikarabellang bakeng sa ho fana ka litšebeletso tse ikhethang.

Meralo e nepahetseng ea leloala e entsoeng ke sehlopha sa rona e nahanela bophelo ba ts'ebeletso; grind & matla a sebetsang hantle le litšobotsi tsa ore, hammoho le lithibelo tsa potoloho ea costumer holimo le tlase ho leloala la leloala.

HG Casting e atlehile ho sebelisa tšepe ea motsoako oa ASTM 2074/L2B ho etsa lilara tsa AG/SAG. Tlas'a thepa ena, nako ea bophelo ba liner tsa rona e ka ntlafatsoa. Bareki ba rona ba Australia ba ne ba laetse lithane tse fetang 10,000 ka selemo tsa li-liner tsena tsa leloala.

E le setsi sa ho lahla, HG Casting e boetse e na le moralo oa SAG Semi-Autogenous Grinding Mill Liner le AG Autogenous Grinding Mill Liner . Ka kakaretso, sebaka sa lifti le sekhutlo, sebaka se bulehileng sa grate le boholo ba lesoba, le moralo le bokhoni ba ho phahamisa pulp. E 'ngoe le e' ngoe ea lihlooho tsena e bile le lipatlisiso tse ngata, 'me ho hatisitsoe lithuto tse ngata tsa thuto ea ho iphetola ha lintho. Ho ipapisitsoe le boiphihlelo, meralo ea li-mill liner e se e lebile molemong oa ho phahamisa likhetla tse bulehileng haholoanyane le moralo oa grate ho thusa ho holisa tšebeliso ea potoloho e pshatlang majoana le matla a leloala la SAG. Phahamiso ea Mill e eketsoa ka li-shell lifters lipakeng tsa 2.5:1 le 5.0:1. Lethathamo lena la karo-karolelano le boleloa ntle le ho bua ka sefahleho sa sefahleho; Likarolong tse lekanang tsa sebaka ho ea ho bophahamo, li lifti tse nang le li-angle tse kholo tsa sefahleho li tla ba le mathata a fokolang a ho paka ha li le ncha empa li na le maemo a holimo ho feta a sefahleho se moepa. Moralo oa lifti ea pulp e ka ba taba ea bohlokoa bakeng sa limilone tsa SAG, haholo bakeng sa leloala le leholo. Bophahamo bohle ba leloala boa eketseha, matla a hlokahalang a li-pulp lifters a hola ka ho lekana le bophahamo ba leloala.

Semi-autogenous grinding mill liner e boetse e bitsoa SAG mill liner, Autogenous grinding mill liner e boetse e bitsoa AG mill liner. Ho tloha ka selemo sa 2014, H&G Machinery e fetohile e 'ngoe ea baetsi ba liner tsa AG/SAG tse kholo ho tsoa Chaena. Ho sa tsotellehe hore na u batla thepa efe, tšepe ea manganese kapa tšepe ea Ni-hard kapa Cr-Mo kapa tšepe ea alloy; Ho sa tsotelehe hore na u hloka mofuta ofe oa li-mill liner. sebopeho sa leqhubu kapa sebopeho se phahamisitsoeng se holimo kapa sebopeho se hatetsoeng; H&G Machinery ke khetho ea hau ea pele.

Ke Efe U Khethang Li-Liner tsa H&G Machinery's AG/SAG Mill?

- Phihlelo e ruileng. H&G Machinery e fana ka lithane tse fetang 10,000 tsa mefuta e fapaneng ea liner.

- Lintho tse fapaneng. Re fana ka lisebelisoa tse fapaneng ho lumellana le maemo a fapaneng a mosebetsi. Joalo ka tšepe ea manganese, tšepe ea Ni-hard, tšepe ea Cr-Mo, le litšepe tse ling tsa alloy.

- Sistimi e felletseng ea QC. H&G Machinery e fana ka sistimi e felletseng ea taolo ea boleng le lirekoto. U ka sheba litokomane tsohle le lirekoto ha u re etetse kapa re u romella tsona.

- OEM tšebeletso. H&G Machinery e ka etsa liner tsa hau ho latela moralo oa hau kapa moralo oa rona oa moenjiniere.

Mosebetsi oa AG SAG Mill Liner

Semi-autogenous grinding le autogenous grinding ke leloala la phofo le bophara ba cylinder e kholo le ho potoloha butle. Thepa e feptjoa ka leloala ka koranteng e sekoti qetellong ea ho fepa. Tlas'a ho sebelisana ha lisebelisoa, thepa e sithabetseng ho ea ho fineness e itseng e feta ho tsoa Koranta e sekoti qetellong e lokolloa ka ntle ho mochine. Liner ke karolo ea bohlokoa ea mochine oa ho sila.

- Mochine o phahamisang o phahamisa thepa ho ea bophahamong bo itseng, phello ea ho oa ha mahala, le phello ea likhohlano pakeng tsa ho ferekanngoa pakeng tsa lisebelisoa, e le hore lisebelisoa li pshatlehe le fatše hantle.

- Sebopeho sa boto ea sekoahelo sa ho qetela se batla se khethehile. Lisebelisoa tse ngata li eketsoa ka koung ea ho fepa. Likaroloana tse nyane tsa thepa li oela ka mokhoa o ts'oanang setsing se ka tlase sa silindara ka holim'a leqhubu la leqhubu ebe li hasana mahlakoreng ka bobeli, ha likaroloana tse kholo li na le matla a maholo a kinetic. : Sebaka sa projectile se lula se lebile lehlakoreng le hole, empa karolo ea eona e tla thula ka mokhoa o ke keng oa qojoa le mahlakore a mabeli a leqhubu la maqhubu. Ka lebaka la phello ea counterattack ea lesela la leqhubu, e ka thibela thepa hore e se ke ea "khethoa" ka likotoana tse kholo le tse nyenyane tsa axial, e le hore likarolo tse kholo tsa thepa li ka aroloa ka tsela e tšoanang. Thepa e mahoashe e khutlile ho tloha pheletsong ea ho tsoa ka lehlakoreng le ka tlase, joalo ka boloko ba thepa e sa tsoa eketsoa, e oela ka ho lekana bohareng ba moqomo ebe e arola mahlakoreng ka bobeli. Lisebelisoa tse kholo le tse ntle li tsamaea ka lehlakoreng le fapaneng ho latela tataiso ea axial ka tlaase ho Sechaena se nolofalitsoeng, kahoo li na le phello ea ho sila.

- Ka bobeli letlapa le phahamisang le nang le sebopeho sa T le wave plate li na le mosebetsi oa ho tiisa boloko. Ka ho potoloha ha leloala, boemo ba "block" bo ntse bo eketseha, 'me matla a khatello a nyamela ka potlako' me a fetoha tsitsipano ha borokho ba "arched" bo nyolohela holimo 'me bo putlama e le hore khatello ea maikutlo hang-hang e hlahisoang ke ts'ebetso e tsoelang pele ea ho khutlisa e tla etsa hore thibela li-monomers li arohane, ho fella ka ho sila.

Ho kenngoa ha AG / SAG Mill Liners

Mosebetsi oa ho Lokisetsa

- Lokisetsa tsohle tse hlokahalang ho fetola liner tsa leloala.

- Sheba sebopeho le boholo ba lipoleiti tsohle tsa liner, tlosa mapheo a moriri, ho lahla slag, joalo-joalo;

- Itokisetse ho khutlisa liboutu tse hlokahalang, linate le li-washer le lisebelisoa tse ling;

- Hlahloba ka hloko hore na lisebelisoa tsa ho phahamisa, lisebelisoa le lisebelisoa li bolokehile ebile li tšepahala.

- Lokisetsa matla a tšireletso a 36V bakeng sa mabone a kaho ka har'a tube;

- Pele leloala le emisoa, ho tlameha ho ba le liminerale tse lekaneng ka har'a moqomo o loketseng ho kena le ho tsoa ha liner pele o emisa.

- Basebetsi bohle ba kaho ba tlameha ho roala lisebelisoa tsa ts'ireletso ea basebetsi ho kenyelletsa likatiba tse thata, limaske le lieta tse sa thelleng pele ba kena setšeng.

Mehato ea Tlhophiso

- Tlosa trolley ea lijo 'me u phahamise sekoti se amohelang;

- Tlosa li-bolts tsa ho lokisa likotoana tsa liner ho sireletsa le ho hloekisa likoti tsohle tsa screw. Se ke oa qhaqha li-liner tse fetang 3 ka nako e le 'ngoe;

- Phahamisa li-liner tsa AG tse tlositsoeng ka bonngoe ka ho khanna, ebe u fanyeha letlapa le tla nkeloa sebaka ka har'a tube;

- Tlas'a tataiso ea molaoli ea hoisting, sebelisa koloi ho roala thapo ea terata ka masoba a bolt ea silindara, ho hula boto ea lesela sebakeng se hlokahalang sa ho kenya, ebe o sebelisa crowbar ho otlolla screw le nut. Tlatsa masoba a mabeli a screw a boto ea lining ka ho fapanyetsana ka mehele ea hemp (e seng ka tlase ho 5 sehlopheng ka seng), kenya selikalikoe sa rabara se emisang ho lutla le washer e bataletseng ebe u tiisa nate;

- Ha u kenya leloala la leloala, li-deposit le litšila sebakeng sa ho kenya li lokela ho hloekisoa;

- Haeba ho fumanoa hore sets'oants'o sa sebaka sa ho kenya poleiti ea marang-rang se tsofetse haholo, sekoti sa ho lahla se tlameha ho nkeloa sebaka pele poleiti ea grid e nkeloa sebaka;

- Kenya trolley ea phepelo ea ho hlaphoheloa le funele ea morafo.