PNG halts Ok Tedi copper mine over covid-19 cases

Papua New Guinea has halted operations at its massive Ok Tedi copper and gold mine for at least 14 days after seven workers tested positive for covid-19 and the country faces a surge in infections, with local authorities saying they could potentially reach thousands in the next few months.

The cases were recorded despite Ok Tedi Mining shutting down all charter flights in late July.

THE SUSPENSION, WHICH BEGAN ON WEDNESDAY, IS EXPECTED TO CUT THE MINE’S OUTPUT BY 4,000 TONNES OF COPPER AND 12,000 OUNCES OF GOLD

Oki Tedi Mining said on Thursday that it had traced the infections back to a single worker, who is believed to have contracted the virus from a person who flew from capital Port Moresby to the port town of Kiunga late last month.

“The employee is currently working in our operations, travelling to and from work on buses. It is likely that more people have been infected, giving rise to an unacceptable risk of accelerated transmission within the Ok Tedi workforce,” the mine’s chief executive Musje Werror said in a statement.

Werror said the state-owned mine will use the idled time to implement further contact tracing, testing and isolation procedures with the purpose of limiting any further spread of the virus and plans to resume safe operations as soon as possible.

Shutdown impact

The 14-day shutdown will have broader economic impacts, the company said. Oki generates a significant amount of foreign currency inflows into PNG and the suspension is likely prevent about $40 million from coming into the country.

The suspension, which began on Wednesday, is also expected to cut the mine’s copper output by about 4,000 tonnes and gold production by about 12,000 ounces, it said.

PNG has now recorded 163 confirmed cases — low by global standards — but with a record jump of 39 in a day, and up from 11 just three weeks ago. There have also been three deaths.

Oki mine, which is 67% owned by the national government and 33% owned by the country’s Western Province, is now strictly limiting the movement of staff between its operations. In addition, it’s seeking support to end commercial air services into Kiunga.

The perfect circumstance would be when even put on occurs throughout the jaw plate location, making use of all the manganese teeth, eliminating the demand to execute the “turn”, or modification manufacturing.

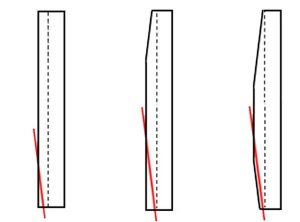

This is difficult, however, due to the fact that there are locations where we can not stay clear of a lot more extreme wear than in others, mainly because of the crushing movement geometry, such as in the fixed jaw plate reduced tip and the central location of the swing jaw plate, so a turn must be carried out to attain much better efficiency and also usage. We suggest a double turn, to put it simply:

Movable Jaw Plate: the same procedure is applied to the swing jaw plate because although the wear occurs in the central area, it rarely occurs in the exact middle of the jaw plate.

Fixed Jaw Plate – use until wear of about 50% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100% occurs in this new lower area. Conclude using the remaining 50% of the life cycle of this extremity.

H&G Machinery is the professional crusher jaw plates manufacturer in China. We have the professional engineer wait for your ask!

@Nick Sun [email protected]

Post time: Aug-07-2020