Pretium posts strong Q2 results

Pretium Resources‘ Brucejack underground mine, 65 km north of Stewart, produced 90,419 oz. of gold in the second quarter, close to the previous year’s figure of 90,761 oz., in spite of the covid-19 pandemic.

The company, which has not seen any significant interruptions so far from the pandemic, reiterated its production guidance issued in February of 325,000 oz. to 365,000 oz. of gold for the year. Pretium’s sole producing mine, Brucejack marked its one-millionth ounce of gold production during the quarter, after beginning commercial production in July 2017.

The company reported net earnings of $32.5 million (adjusted $49.2 million) on revenues of $166 million for the quarter. Its all-in sustaining cost per oz. of gold was $911, down from $940 in the same quarter of last year, while it sold its gold production at an average price of $1,738 per oz., up from $1,319 per oz. last year.

“Brucejack delivered another profitable quarter with record free cash flow,” said Jacques Perron, president and CEO of Pretium in a release.

“In the first six months of the year, the mine produced 173,307 ounces of gold generating C$293.1 million in revenue and C$124.6 million in free cash flow, surpassing our full-year free cash flow target.”

During the quarter, an average of 3,596 t/d with a head grade of 8.9 g/t gold were processed at Brucejack, with gold recoveries averaging 96.7%. The mill has a capacity of 3,800 t/d, but throughput was lower due to scheduled and unscheduled maintenance, a focus on lateral development at the mine and stope availability.

While production guidance remained steady, the company has increased its cost guidance for the year, with all-in sustaining costs now expected to fall between $960 and $1,120 per oz., up from a previously anticipated range of $910-$1,060 per oz.

Included in the new cost guidance is the additional expense of covid-19 protocols, estimated at $15 million, and additional drilling budgeted at $6.5 million.

The company also introduced a reverse-circulation (RC) drilling grade control program during the quarter. In addition, diamond drilling, which was put on hold at the start of the pandemic, resumed, targeting reserves near mine infrastructure.

No cases of covid-19 have been detected at Brucejack, however, the company reported a fatality at the mine last week.

With its quarterly results, Pretium included an update on its 2020 regional exploration program, which is focused on the A6 zone, 14 km northeast of Brucejack. About 10,000 metres of drilling is planned to target Eskay Creek-style volcanogenic massive sulphide mineralization.

Additional exploration drilling is planned for the Koopa zone, 30 km southeast of Brucejack, the Hanging Glacier zone, 4.5 km northwest, and the East Snowfield zone, 6 km north of the mine.

Maintenance for these parts must be carried out only by trained or authorized personnel, but the inspection can be performed by the operator.

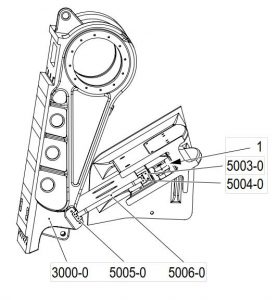

Worn components should be replaced in good time to avoid damaging the toggle plate or toggle seats, with a consequent need for expensive repairs. Sandvik recommends exchanging the toggle plate (5006-0) and the toggle seats (5004-0), (5005-0) at the same time.

Toggle plate

The toggle plate (5006-0) is a part of the setting adjustment system. It forms a link between the moving jaw (3000-0) and the setting arrangement (1). The toggle plate is exposed to high pressure and heavy wear and is replaceable. If the minimum discharge setting cannot be reached, this could be an indication that the toggle plate is worn down. Check it and if necessary replace the toggle plate with a new one. Stress can create cracks or bend the toggle plate. If the toggle plate shows signs of cracks or is bent it is necessary to replace it with a new one.

Toggle seat

The toggle plate (5006-0) is located by a toggle seat (5004-0), (5005-0) at each end. The toggle seats are hardened. But since they are exposed to high pressure and heavy wear, they are replaceable. If the toggle seats lose their shape it is necessary to replace them with new ones.

- 3000-0 Jaw (moving)

- 5005-0 Toggle seat, lower

- 5006-0 Toggle plate

- 5003-0 Toggle seat holder

- 5004-0 Toggle seat, upper

- 1 Setting arrangement

Setting measuring gauge

The discharge setting is the closest distance between the jaw plates at the bottom of the crushing chamber. The distance varies with the crushing movement of the moving jaw – the smallest distance along this movement is called the CSS (closed side setting). It’s unlikely that the crusher stops when this distance is as small as possible, so the CSS must be measured on a running crusher.

A gauge for CSS, consisting of a rod with discs, is supplied with the crusher. The diameter of the smallest disc, that is in contact with both the stationary and moving jaw plate when and where the distance is as small as possible, gives an appreciation of the CSS. The disc simulates the section of a spherical or ellipsoid stone.

The measuring tool is composed of a set of rubber discs with different diameters, one rod with threaded ends, nuts, fixing washer and a nylon line for gauge lifting. When the rod is suspended by the line, it will maintain the mounted disc in a horizontal position.

Measuring instructions

Run the jaw crusher empty. Clean the feeder from process material, before measuring begins.

- Make an assumption of the diameter of disc to use. Mount it on the rod.

- Lower the measuring tool by the line along the stationary jaw plate. The disc should be in contact with two crests.

- If the measuring tool passes the bottom end of the jaw plates, the disc is too small, but if the measuring tool is stopped before it reaches the bottom end, the disc is too big.

- When the correct disc is mounted, it is in a horizontal position touching two stationary jaw plate crests and barely touching one moving jaw crest at the bottom end of the jaw plates. This means that the disc diameter is equal to the CSS.

- If a specific CSS is required, use the corresponding disc diameter and adjust the setting arrangement to obtain the required setting.

- The crusher has accessories to help to adjust the CSS to a minimum. Simply by replacing the wear plates behind the jaw plates with thicker jaw shim plates (and exchanging the support bars) the minimum CSS can be decreased.

@Nick Sun [email protected]

Post time: Aug-14-2020