China Wholesale Ni Hard Alloy Factory - SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner SAG Mill Liner and AG Mill Liner L2C L2B Liner Chrome Moly Mill Liner Cr-Mo Mill Liner – H&G

Short Description:

China Wholesale Ni Hard Alloy Factory - SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner SAG Mill Liner and AG Mill Liner L2C L2B Liner Chrome Moly Mill Liner Cr-Mo Mill Liner – H&G Detail:

Product Description

SAG Mill Liner AG Mill Liner L2C L2B Mill Liner Cr-Mo Mill Liner from H&G use Cr-Mo materials (AS2074 Standard), SAG Mill Liner AG Mill Liner L2C L2B Mill Liner Cr-Mo Mill Liner provides superior impact and wear resistance in all semi-autogenous milling applications.

To choose the right material for the right application is our mission , we are always working together with our customer to achieve this .The right material is upon to:

1. The mineral ground

2. Milling data information

3. Maximum grinding media diameter (mm)

4. Grinding media filling degree (%)

In general, Item M1 used for high impact condition ,P1 used for low impact condition. It shall change according to your mineral processing.

Specification Available

|

Code |

Chemical Elements(%)SAG Mill Liner AG Mill Liner L2C L2B Mill Liner Cr-Mo Mill Liner |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 |

0.4-0.7 |

0.6-1.0 |

1.8-2.5 |

0.25-0.5 |

0-0.5 |

≤0.04 |

≤0.06 |

|

M1 |

0.3-0.45 |

0.4-0.7 |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 |

0-0.5 |

≤0.04 |

≤0.06 |

Physical Property & Microstructure

|

Code |

Hardness(HB) |

Ak(J/cm2) |

Microstructure |

|

P1 |

325-375 |

≥50 |

P |

|

M1 |

350-400 |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Note: Adjust the chemical content or add other alloying elements of SAG Mill Liner AG Mill Liner L2C L2B Mill Liner Cr-Mo Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Our SAG Mill Liner AG Mill Liner L2C L2B Mill Liner Cr-Mo Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

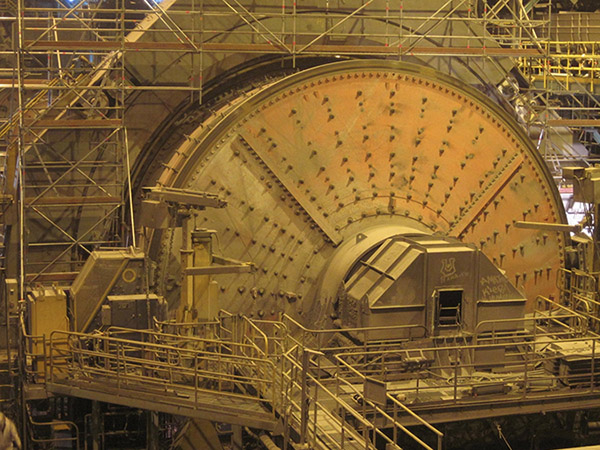

Semi-autogenous mills or SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening. Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stages.

Lower lifetime cost

The range of mill sizes and versatile applications allow SAG milling to be accomplished with fewer lines than conventional set-ups. This, in turn, contributes to lower capital and maintenance costs for a SAG mill circuit.

Versatile applications

SAG milling extends itself to many applications due to the range of mill sizes available. They can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill and some or all of the work done by a ball mill.

SAG mills are also an optimum solution for wet grinding since crushing and screening in these cases can be difficult, if not impossible.

Efficiency through automatic operation

HG’s process engineers will assist you in creating an efficient software-driven process, from circuit design to start-up and optimization, to ensure you get your desired grinding results.

Through automatic operation it is possible to save power, grinding media, and linear wear, while increasing capacity.

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto "High Quality, Aggressive Price, Fast Service" for China Wholesale Ni Hard Alloy Factory - SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner SAG Mill Liner and AG Mill Liner L2C L2B Liner Chrome Moly Mill Liner Cr-Mo Mill Liner – H&G , The product will supply to all over the world, such as: Macedonia, Oman, Algeria, If any item be of interest to you, please let us know. We will try our best to satisfy your requirements with high quality products, the best prices and prompt delivery. Please feel free to contact us at any time. We will reply you when we receive your inquiries. Please note that samples are available before we start our business.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.