Centamin earnings soar on higher gold prices, output

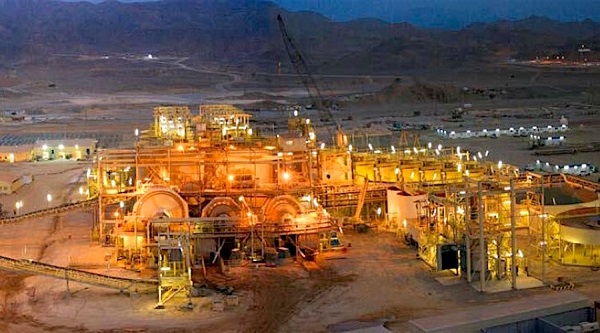

Egypt-focused gold miner Centamin (LON:CEY) (TSX:CEE) posted on Tuesday a jaw-dropping 280% rise in net profit for the first half of 2020 compared to the same period last year, on the back of higher output from its flagship Sukari mine, falling costs and soaring metal prices.

The company reported net income of $74.8 million, up from $19.7 million in the first half 2019. Production also rose — by 9% to 256,084 ounces, while the average price of gold sold climbed by 27% to $1,657 an ounce.

Sukari, which began operations in January 2010, comprises a large open pit and an underground mine. The asset, the only operating gold mine in Egypt, remains on track to meet 2020 production guidance of between 510,000 and 525,000 ounces of gold.

Centamin, which terminated talks with Endeavour Mining (TSX: EDV) for a possible takeover earlier this year, said it has 186% more free cash flow, standing at $101.96 million. The figure came after the distribution of $114 million in profit share and royalty payments to Egypt.

The miner also declared a second interim dividend of $0.06 a share, equivalent to 68% of its free cash flow. The company will pay the dividend to shareholders in September, it said.

The company has proved resilient to recent challenges, beyond those brought by the covid-19 pandemic. After about six months without a top boss, it appointed in April Martin Horgan as its new chief executive officer.

Centamin has also gone through some major board changes. Those include seeing Josef El-Raghy migrate from executive chairman to chairman, 18 years after becoming managing director.

Egypt in the spotlight

Aside from an almost 30% surge in gold prices so far this year, Centamin has also benefitted from Egypt’s new drive to attract foreign miners. Until February, it was the only international company with a mining license in the country. But on February 13, Canada’s Aton Resources (TSX-V: AAN) secured a mining permit — the first one granted in 15 years.

A month later, Cairo began auctioning 56,000 square kilometres of exploration concessions in the Eastern Desert.

Egypt recently extended the auction’s original July deadline to September 15 due to delays caused by the coronavirus pandemic and to extend the opportunity to more potential bidders.

Centamin’s new boss said in July the company would participate in the ongoing auction.

“We have significant infrastructure in Egypt and leveraging that off would be a good thing,” Horgan said at the time, adding that the miner was waiting for details on the process before preparing any bids.

Unlike Egypt’s natural gas sector, its mineral wealth remains largely under-explored and undeveloped.

The lack of activity was due, in part, to the nation’s past system of royalties and profit-sharing agreements. They made it difficult and unprofitable for miners to explore for and exploit minerals.

Egypt’s Ministry of Petroleum and Mineral Resources revealed in June the discovery of a gold deposit with estimated resources of 1 million ounces.

While the government did not provide details on the methodology used to determine the deposit’s size, it noted it expected at least $1 billion in investments related to the development of the deposit over the next 10 years.

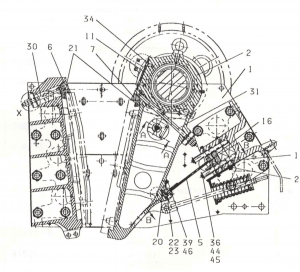

Jaw plates can either be turned end for end or replaced depending on their wear. The jaw dies can be turned once after their installation before they need to be replaced.

Dismantling

Fixed Jaw Plates

- Clean the jaw die lifting holes. Remove stones and sand from the jaws. Also, remove material packed between the jaw and side plates.

- Hold the jaw die up with a hoist and lifting hooks.

- Remove the hex nuts and the spring packages.

- Remove T –head bolts (30), tightening wedge (6), and upper wedge (21). Be careful not to drop the jaw in the gap and cause damage.

- Lift out the jaw dies.

Movable Jaw Plates

- Clean the jaw die lifting holes. Remove stones and sand from the jaws. Also, remove material packed between the jaw and side plates.

- Hold the jaw die up with a hoist and lifting hooks.

- Remove the hex nuts and the spring packages.

- Remove T –head bolts (31), tightening wedge (7), and upper wedge (21). Be careful not to drop the jaw in the gap and cause damage.

- Lift out the jaw die.

Assembly

Before re-assembly make sure that the support surfaces are clean. The jaws should be in continuous contact with the support surfaces.

Replace or reverse worn parts. If the wedge contact surface on the ends of the jaw dies is distorted from crushing, the original angle must be established by grinding before assembling the jaw die wedges to assure good contact and seating area.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Aug-07-2020