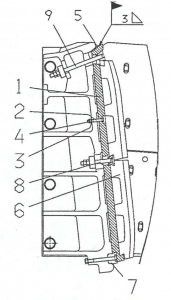

Jaw Crusher Intermediate Plate

The intermediate plate is an important jaw crusher wear parts. Fitting an intermediate (backing) plate behind the fixed jaw die reduces the nip angle of the crusher. The intermediate plate reduces the feed opening and the setting range by approximately the same amount as its thickness. However, the intermediate plate does not, under normal circumstances, allow the user to use a smaller setting than the minimum recommended setting.

- INTERMEDIATE PLATE

- INTERMEDIATE PLATE BOLT

- INTERMEDIATE PLATE WASHERS

- INTERMEDIATE PLATE NUTS

- FILLING WEDGE

- JAW DIE

- LOWER WEDGE

- CENTER JAW DIE BOLT

- UPPER JAW DIE BOLT

If available with the specific jaw crusher model, an intermediate plate may be used for the following reasons:

1. To improve the nip angle (by decreasing the nip angle) when crushing slippery or round material (material that is difficult to bite).

2. To increase the length of the crushing zone (and thus increase the life of the jaw dies) when the feed material is consistently smaller than the crusher’s input capacity.

The intermediate plate is not available for all models. Moreover, intermediate plates are available in more than one thickness for certain model crushers. Before installing an intermediate plate consult Qiming Machinery if it fits your application.

Before installing the intermediate plate, remove the jaw dies or jaw die from the frame. Clean the contact surfaces of the intermediate plate and the frame and ensure that they are in good condition. Lift the intermediate plate and place on top of the lower wedge (7) or place the guiding surface of the intermediate plate in the groove from where the lower wedge has been removed if the lower wedge has been removed, use its fixing bolts in the intermediate plate. Fasten the plate with bolts (2), washers (3), and nuts (4). Then hammer the wedge (5) between the intermediate plate and frame and weld it to the intermediate plate.

Notice: When welding fastens the ground cable directly to the intermediate plate and as close to the welding point as possible.

After installing the intermediate plate install the fixed jaw dies. Note that the jaw bolts used with the intermediate plate must be longer than standard.

After installing the intermediate plate adjust the crusher setting. If the Crusher is equipped with mechanical setting adjustment, check and adjust the tension spring as well.

Mr. Nick Sun [email protected]

Post time: Nov-13-2020