Sumitomo predicts record loss as covid-19 hits nickel project

Japanese trading house Sumitomo Corp on Friday forecast a record net loss of 150 billion yen ($1.4 billion) for the year to March due to hefty one-off losses including a writedown on its Ambatovy nickel project in Madagascar amid the covid-19 shock.

“We have been hit hard by the coronavirus pandemic, especially in metals, machineries and resource/chemical areas,” Chief Financial Officer Masaru Shiomi told a news conference.

“Tough business conditions will likely continue through this year (to March),” he said.

The loss warning, after a profit of 171 billion yen in the last financial year, reflected an estimated one-off loss of 250 billion yen, including an impairment loss of 55 billion yen on Ambatovy it booked in the April-June quarter and other potential losses in steel products, transportation and construction machinery, he said.

“We plan to step up restructuring in unprofitable areas, which may lead to one-off losses,” Shiomi said, without elaborating further.

Sumitomo suspended operation at Ambatovy and its San Cristobal silver-zinc-lead mine in Bolivia in March to prevent the spread of the coronavirus.

It resumed operation at San Cristobal in May, but it expects Ambatovy to restart operations only in the January-March quarter.

It expects Ambatovy to book a 93.7 billion yen loss this year.

Sumitomo also warned that there is a risk for the trading house to book a further impairment loss on Ambatovy if the business environment deteriorates due to any delay to the planned restart, or if nickel prices slump.

Sumitomo’s stake in Ambatovy is due to rise to 54.17% in September from 47.67% currently as Canadian partner Sherritt International is restructuring its debt.

For the April-June quarter, it reported a net loss of 41.0 billion yen, against a profit of 79.7 billion yen a year earlier.

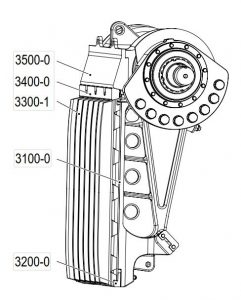

To ensure optimum performance and cost-effective production it’s important to frequently inspect the following parts and to replace them before they are completely worn out.

- 3500-0 Deflector plate (moving jaw only)

- 3400-0 Clamping bar

- 3300-1 Jaw plate

- 3100-0 Wear plate

- 3200-0 Support bar

Jaw plates

The wear pattern and the adjustment of the jaw plates have a great effect on the crusher’s capacity. Crushers can be fitted with jaw plates with different patterns and profiles to suit different crushing duties.

Jaw plates often get worn more at one end or a spot close to one end. Therefore, their life can be extended by reversing them (turning them upside-down).

If the jaw plates are worn down at the bottom end and then reversed, there is a risk that the nip angle becomes too large in the upper part of the crushing chamber. This can create a reduced grip on the material with a consequently decreased capacity. Sandvik recommends exchanging the jaw plates if this occurs.

Several factors affect the wear of the jaw plates, so it’s impossible to generalize when and how to reverse or exchange them. Check the wear pattern regularly and make a judgment of when to reverse or exchange the jaw plates. In general, if the jaw plates are frequently reversed, the wear will be more uniform and will have less effect on the nip angle.

A simple rule is:

- If the tooth height of a part of the jaw plate is 30 % reduced (70 % remaining) it is time to reverse for the first time (teeth are measured from base to top).

- If a part of the jaw plate is worn down almost in level with the original tooth base it is time to reverse for the second time.

- After the jaw plate is worn down in level with the tooth base and reversing won’t help, it is time to exchange the jaw plate.

Often it is advantageous to replace the jaw plate before it is completely worn out.

Deflector plate

The deflector plate (3500-0) is fitted on the upper part of the moving jaw to protect the jaw from large rocks. Since this part is exposed to high pressure and heavy wear it is replaceable. The deflector plate (3500-0) is hollow. If it becomes curved in, or a hole is worn in, it needs to be replaced.

Clamping bar

The clamping bar (3400-0) is fitted above the jaw plate (3300-1) to lock it to the jaw. This part is exposed to high pressure and heavy wear so it is replaceable. When a clamping bar (3400-0) is no longer straight or in full contact with the jaw plate it needs to be replaced.

Wear plate

A replaceable wear plate (3100-0) is sandwiched between the jaw plate (3300-1) and the jaw. It protects the jaws from arching under heavy loads. When a new jaw plate (3300-1) is no longer in contact with the whole surface of the wear plate (3100-0) it is necessary to replace the wear plate.

Jaw shim plate

A replaceable jaw shim plate can instead of a wear plate be sandwiched between the jaw plate and the jaw. The jaw shim plate does not only protect the jaw from arching under heavy loads, but is also used to decrease the nip angle or minimum CSS.

Support bar

The support bar (3200-0) supports the bottom edge of a jaw plate (3300-1). Since this part is exposed to high pressure and heavy wear, it is replaceable.

Cheek plate

The sides of the crushing chamber are protected with cheek plates on the left side (1103-0) and right side (1104-0). Since these are exposed to high pressure and heavy wear (especially in the lower part of the crushing chamber), they are replaceable. Exchange a cheek plate when there is an obvious cavity in it (especially in the lower part).

@Nick Sun [email protected]

Post time: Aug-14-2020