Professional China Blow Bar - Blow Bar – H&G

Short Description:

Professional China Blow Bar - Blow Bar – H&G Detail:

Product Description

Hammers are a critical part when it comes to crushing with Horizontal Shaft Impactors. The metallic composition of the hammers matters greatly; choosing the wrong bar for your application may decrease production, and increase repair/replacement costs. The hammers can be made from the hybrid alloy, manganese, low chrome, high chrome, and high chrome ceramic. Below are the best-suited applications per hammer material:

High Chrome: asphalt, highly abrasive materials, smaller feed size

Medium Chrome: most steel contaminants, some asphalt, larger feed size

Low Chrome: concrete, demolition, aggregates, heavy steel contaminants, very large feed size

Manganese: abrasive materials, asphalt, concrete, light aggregates, some steel or rebar contaminants, larger feed size

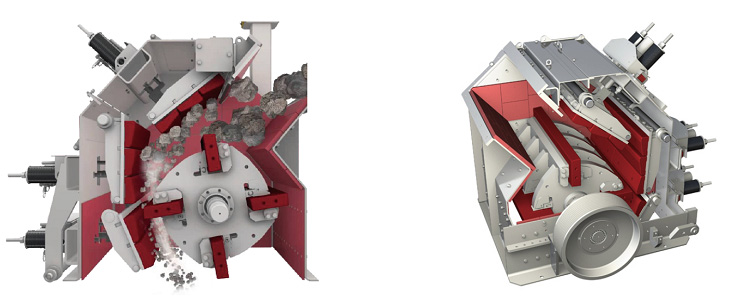

Vertical Shaft Impactors (VSI) consist of a feed hopper, feed tube, a rotor, and either stationary anvils or rock shelves. Essentially, feed material drops through the feed tube into the rotor, which, through centrifugal force, throws the material against stationary anvils made up of composite metal alloys or rock shelves. When the rock impacts the anvils or rock shelves, it shatters along natural stress lines, creating a uniform, cubical product. This method is both economical and simple to operate. The VSI has the best rate of production of smaller sizes (- ½”) as it is the only crusher that does not close off the discharge side to make a smaller product. But are also limited in feed size both by the feed tube and table configurations.

Impact Crushers produce the most uniform cubical shape for finished products, due to its consistent ability to uniformly break apart aggregates through striking. Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft Impactor. Impact crusher machines are available as stationary, track, or mobile units, and can be used in the primary, secondary, or tertiary position in the Producer’s line up. Impact crushers can be subject to high wear and operating costs and high production of fines.

MAIN BRANDS SUPPORT:

Metso, Sandvik, Barmac, SVEDALA, Omnicone, EXTEC, Maxtrak, Keestrack, Symons, Hazemag, Cedarapids, Telsmith, McCloskey, Trio, Powerscreen, Kleemann, Terex, Pegson, Kue Ken, Parker, Shanbao, SBM, Zenith, LIMING, MINYU and other famous brands.

Product Package

Steel Pallet. And Customized according to special packing requirement

Application

The Aggregate Industry (Cement, Ready-Mix Concrete, Asphalt, Crushed Stone, Sand & Gravel), wants to process rock, sand, and gravel into a salable product as efficiently and inexpensively as possible. One such way to process these materials is sending gravel, rock, and sand through an Impact Crusher, which breaks up the material by either striking it with a rapidly moving blow bar or by throwing it into a stationary anvil where it breaks upon impact.

Impact Crushers may be used as primary, secondary, or tertiary crushers depending on the Producer’s final-product-size needs. Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industries. Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producers. Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI). While the ultimate design of each type of impactor is to crush rock, their methodologies differ.

Horizontal Shaft Impactors (HSI) consist of a hopper, two or three aprons (curtains), a rotor, and hammers (blow bars). Essentially, large products are fed into the hopper where they come into contact with hammers on a spinning rotor which crushes the material into smaller pieces. As the larger material gets impacted by the hammers it comes into contact with each apron rebounding it back to the rotating hammers for another round of impacting until it is discharged out of the HSI.

HSI gradation is controlled by rotor speed, the more speed the finer the output; apron gap settings, the smaller the gap the finer the gradation; the number of hammers, depends on crusher speed. Rotor construction can be open or solid, cast or fabricated ceramic. If the impactor is used in the primary position, a massive solid rotor is advised due to its high inertia for optimum crushing performance and solid backing support for the hammers resulting in longevity and lower costs. If the impactor is in the secondary or tertiary position, then efficient open style rotors and heavy gravity hung aprons will deliver consistent performance when crushing aggregates or recycled asphalt products.

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Professional China Blow Bar - Blow Bar – H&G , The product will supply to all over the world, such as: Oman, Amsterdam, Germany, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.