Reasonable price Metso Crusher - Metso Jaw Plate – H&G

Short Description:

Reasonable price Metso Crusher - Metso Jaw Plate – H&G Detail:

Product Description

JAW CRUSHER SPARE PARTS is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heat-treatment process. JAW CRUSHER SPARE PARTS has a working life of 10%-15% longer than those made of traditional manganese steel. As per the feedback from customers, the good performance of JAW CRUSHER SPARE PARTS in different working condition greatly decreased the time of examination & repair and the use-cost.

MAIN BRANDS SUPPORT:

Metso, Sandvik, Barmac, SVEDALA, Omnicone, EXTEC, Maxtrak, Keestrack, Symons, Hazemag, Cedarapids, Telsmith, McCloskey, Trio, Powerscreen, Kleemann, Terex, Pegson, Kue Ken, Parker, Shanbao, SBM, Zenith, LIMING, MINYU and other famous brands.

Product Package

Steel Pallet and Customized according to special packing requirement.

Application

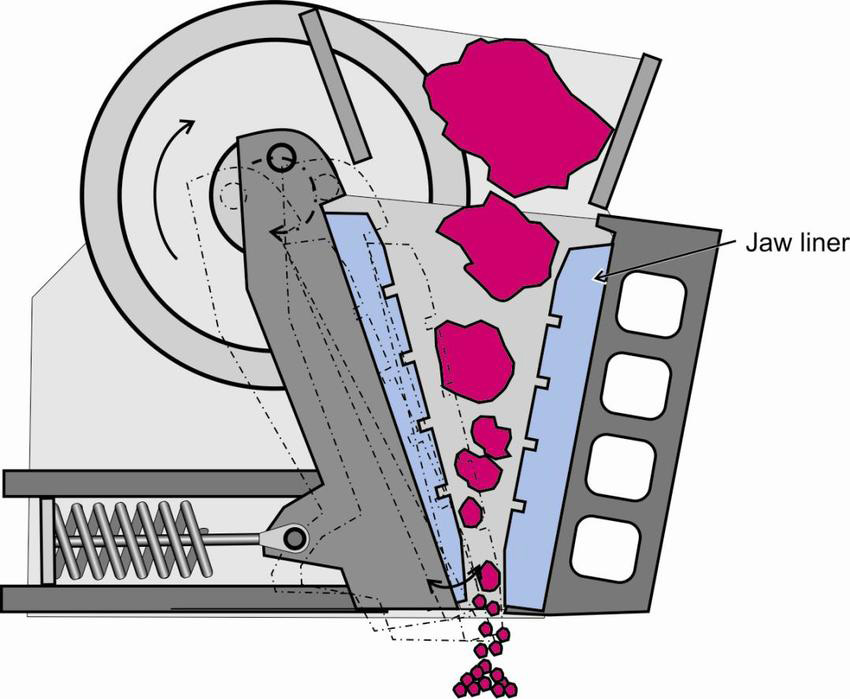

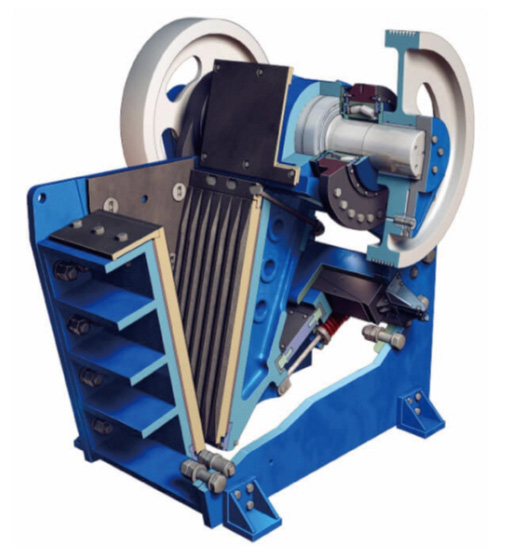

A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V). The movable jaw compresses material against the fixed jaw, crushing the material to the desired size. The material exits the jaw through the bottom of the crusher otherwise known as the discharge opening. Changing the discharge opening controls the product size made by the crusher.

Jaw crushers are mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries.

A jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material.

There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jaw.

Depending on the application requirements, jaw crushers are available in stationary, wheeled portable, and track-mounted options.

Jaw crushers are often designated by the size of the top opening where material enters. The openings tend to be either rectangular or square and are referenced in inches. For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening. 32” being the gap at the top between the jaw dies and 44” being the width between the side plates.

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Reasonable price Metso Crusher - Metso Jaw Plate – H&G , The product will supply to all over the world, such as: Hamburg, Sydney, Denver, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.