Unternehmens Nachrichten

-

Hersteller von SAG-Mühlenauskleidungen – H&G

SAG mill liner manufacturer – H&G SAG mills also known as Semi-Autogenous Grinding Mills are actually grinding mills that come shell diameter to length ratio of about 2 most commonly. Due to their higher aspect ratio, these mills are capable of generating both cascading and thro...Weiterlesen -

Gängige Arten von Mühlenauskleidungen

Common Types of Mill Liners Mill liners are an important component of the grinding mill. They not only protect the shell of the mill from wear and tear but also transfer energy generated by the mill motor to the grinding charge. This increases the efficiency of the mill. In this article, ...Weiterlesen -

Wichtige Überlegungen bei der Auswahl von Mühlenauskleidungen

Key considerations when selecting grinding mill liners Choosing the right grinding mill liners for yourself can be a tedious task. There are so many varieties of mill liners available in the market, each with their respective benefits and uniqueness. Moreover, at times you cannot understa...Weiterlesen -

Vorteile von Komposit-Mühlenauskleidungen

Benefits of Composite Mill Liners Over time, the mill liner technology has constantly been undergoing upgrades and innovation to improve the productivity and safety of the employees. In the old days, only metal mill liners existed. However, now we also have rubber and composite cement mil...Weiterlesen -

Stahlwerksauskleidungen vs. Gummiwerksauskleidungen

Steel Mill Liners vs Rubber Mill Liners When it comes to mill liners, mill liners manufacturers are usually conflicted between which kind of liners should be manufactured: rubber or steel. Each of them has their advantages, and disadvantages, so it can be a tough decision to make. It is a...Weiterlesen -

Schritt-für-Schritt-Anleitung zum Austausch von Kugelmühlenauskleidungen

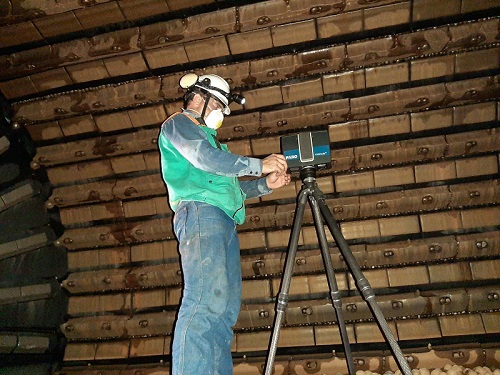

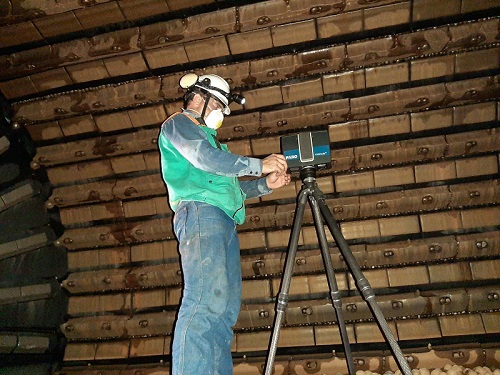

Step by Step Guide to Replace Ball Mill Liners Ball Mill Liner are an extremely efficient variant of mill liners, which is what compels the ball mill liners manufacturers to manufacture them in the first place. If used properly, they may last pretty long. However, at one point or another ...Weiterlesen -

Wann müssen Kugelmühlenauskleidungen gewechselt werden?

When to change ball mill liners? Amongst many types of mill liners for grinding purposes, ball mill liners are at a league of their own. They have a unique structure that in turn gives them unique functionality, which reaps many benefits for us. Generally, it can be confusing to determine...Weiterlesen -

Analyse und Behandlung des Mühlenauskleidungsproblems einer Kugelmühle Ф 2,2 m × 6,5 m

Analysis and treatment of mill liners problem of Ф 2.2m × 6.5m ball mill We have a Russian customer, who has a cement clinker production line, which includes a Ф 2.2m × 6.5m ball mill. One month after the ball mill was put into operation, the mill liners and step liner of the first bin w...Weiterlesen -

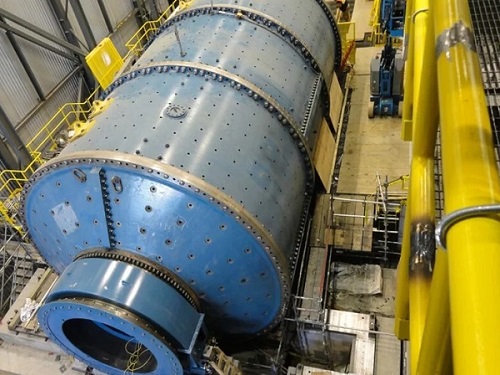

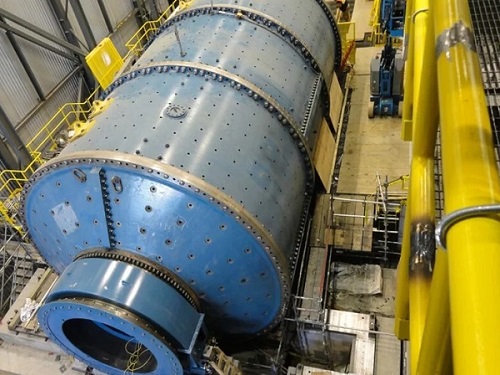

Φ6,0 m x 3,0 m SAG-Mühle und Φ7,3 m x 4,27 m Kugelmühlenauskleidungen Neugestaltung

Φ6.0m x 3.0m SAG Mill and Φ7.3m x 4.27m Ball Mill Liners Redesign Our customer is a gold concentrator. The design capacity of the gold concentrator is 2 000 t / D, and the general hardness coefficient of the ore is 8-10. The ore belongs to the high-temperature hydrothermal altered rock ty...Weiterlesen -

Wie überprüfe ich die Qualität der Brecherverschleißteile?

How to check crusher wear parts quality? What is crusher wear parts? A crushing machine is made up of hundreds of useful parts. Some of the parts crush the stone raw material or ore and lose their strength. Therefore, you need to replace such parts regularly for the proper functioning of ...Weiterlesen -

Erforschung von korrosionsabriebfesten SAG-Mühlenauskleidungen aus legiertem Stahl

Research of Corrosion-abrasion Resistant Alloy Steel SAG Mill Liners Based on customer’s semi-autogenous mill working conditions, H&G Machinery researches corrosion-abrasion resistant alloy steels for semi-autogenous mill liners. Semi-autogenous mill liners are under impact abras...Weiterlesen -

Wie man die Mahlfeinheit effektiv steuert und die Rückgewinnungsrate erhöht

How to Effectively Control the Grinding Fineness and Increase the Recovery Rate For many mineral processing plants, tocontrol of grinding fineness and increase the recovery rate of ore concentrateis an important factor to increase enterprise benefit. So how to effectivelycontrol the grinding f...Weiterlesen