Kev tshaj lij Tuam Tshoj Tuam Tshoj Hazemag APK 40 High Chrome Tshuab Tshuab

Lus piav qhia luv luv:

Peb persistently execute peb tus ntsuj plig ntawm "Innovation coj txoj kev loj hlob, Highly-zoo ua kom muaj kev noj qab haus huv, Kev tswj hwm nqi zog, Credit keeb kwm nyiam cov neeg siv khoom rau Tuam Tshoj Tuam Tshoj Hazemag APK 40 High Chrome Tshuab Tshuab, Peb tam sim no tau xa tawm mus rau ntau tshaj 40 lub teb chaws thiab cheeb tsam. , uas tau txais lub koob npe zoo heev los ntawm peb cov neeg siv khoom txhua qhov chaw hauv ntiaj teb.

Peb pheej ua peb tus ntsuj plig ntawm "Innovation coj txoj kev loj hlob, zoo-zoo ua kom muaj kev noj qab haus huv, Kev tswj hwm kev lag luam khoom plig, Credit keeb kwm nyiam cov neeg siv khoom rau tshuab tshuab , Tuam Tshoj Hazemag Apk 40 High Chrome Tshuab Tshuab, Peb vam khom cov ntaub ntawv zoo, zoo meej tsim, kev pabcuam zoo rau cov neeg siv khoom thiab cov nqi sib tw los yeej kev ntseeg siab ntawm ntau tus neeg muas zaub hauv tsev thiab txawv teb chaws. 95% cov khoom raug xa tawm mus rau kev lag luam txawv teb chaws.

Product Description

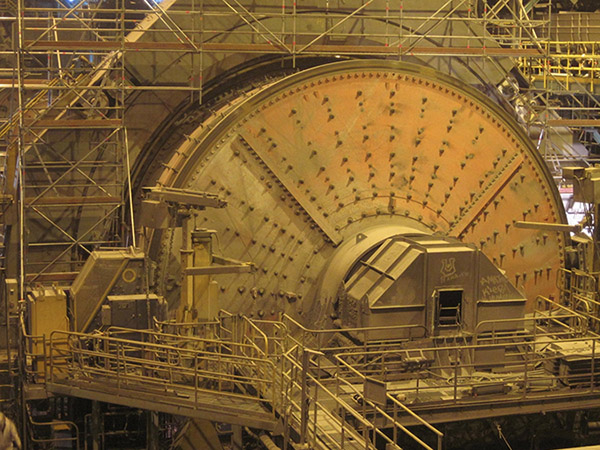

SAG Mill Liner los ntawm H&G siv Cr-Mo cov ntaub ntawv (AS2074 Standard), SAG Mill Liner muab kev cuam tshuam zoo dua thiab hnav tsis kam nyob rau hauv txhua daim ntawv thov ib nrab-autogenous milling.

Txhawm rau xaiv cov khoom tsim nyog rau daim ntawv thov raug yog peb lub luag haujlwm, peb ib txwm ua haujlwm ua ke nrog peb cov neeg siv khoom kom ua tiav qhov no .Cov ntaub ntawv raug yog raws li:

1. Cov pob zeb hauv av

2. Milling cov ntaub ntawv xov xwm

3. Qhov siab tshaj plaws sib tsoo media txoj kab uas hla (mm)

4. Sib tsoo media filling degree (%)

Feem ntau, Yam khoom M1 siv rau qhov muaj feem cuam tshuam loj, P1 siv rau qhov tsis zoo. Nws yuav tsum hloov raws li koj cov ntxhia ua.

Specification Muaj

|

Code |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 hli |

0.4-0.7 hli |

0.6-1.0 |

1.8-2.5 Nws |

0.25-0.5 hli |

0-0.5 hli |

≤ 0.04 |

≤ 0.06 |

|

M1 |

0.3-0.45 Nws |

0.4-0.7 hli |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 hli |

0-0.5 hli |

≤ 0.04 |

≤ 0.06 |

Physical Property & Microstructure

|

Code |

Hardness (HB) |

Ak (J / cm2) |

Microstructure |

|

P1 |

325-375 : kuv |

≥50 |

P |

|

M1 |

350-400 Nws |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Nco tseg: Kho cov ntsiab lus tshuaj lossis ntxiv lwm cov ntsiab lus ntawm SAG Mill Liner raws li cov neeg siv khoom xav tau.

Pob khoom

● Hlau Pallet, Ntoo Pallet thiab Ntoo Box

● Customized raws li kev ntim khoom tshwj xeeb.

Peb Qhov Zoo

Ntawm HG Casting, peb tsim cov qauv tsim tshiab, tshwj xeeb tshaj yog rau txhua tus neeg siv khoom. Peb AG / SAG zeb liners yog tsim los rau cov txheej txheem kev lag luam siab tshaj plaws rau Autogenous Sib Tsoo (AG), Semi-Autogenous Sib Tsoo (SAG), Thawj / Secondary thiab rov sib tsoo pas nrig lossis pob zeb. MGS Casting zeb hauv ob sab phlu tsim los ntawm peb cov kev kawm tau zoo, thiab pab pawg neeg mob siab rau thoob plaws ntiaj teb tau coj koj tag nrho cov kev sib txuas ua ke rau hauv kev txiav txim siab. Txhawb nqa peb cov kab pem hauv ntej Mill Engineers yog ib pab pawg loj ntawm cov kws tsim qauv tsim tshwj xeeb, cov khoom siv chemists, kev tsim khoom thiab cov kws tshaj lij logistics lub luag haujlwm rau kev xa cov kev pabcuam tshwj xeeb.

Optimal zeb designs engineered los ntawm peb pab neeg coj mus rau hauv kev xav txog kev pab cuam lub neej; grind & zog efficiency thiab ore yam ntxwv, nrog rau cov neeg siv khoom Circuit Court txwv ob qho tib si nce thiab nqis ntawm lub zeb hauv ob sab phlu.

HG Casting tau ua tiav los siv ASTM 2074 / L2B alloy steel los tsim AG / SAG zeb liners. Nyob rau hauv cov ntaub ntawv no, peb lub zeb liners ncua lub neej yuav ua kom pom tseeb. Peb cov neeg siv khoom Australia tau xaj ntau dua 10,000 tons hauv ib xyoos ntawm cov khoom siv zeb no.

Raws li ib tug casting foundry, HG Casting kuj muaj tus kheej SAG zeb liner tsim. Nyob rau hauv dav dav, lifter spacing thiab lub kaum sab xis, grate qhib cheeb tsam thiab aperture loj, thiab pulp lifter tsim thiab muaj peev xwm yuav tsum tau txiav txim siab. Txhua yam ntawm cov ncauj lus no tau muaj ntau qhov kev tshawb fawb, thiab ntau cov ntaub ntawv tshawb fawb ntawm evolutionary liner tsim tau luam tawm. Raws li kev paub dhau los, zeb liner tsim tau txav mus rau ntau lub plhaub lifter volumetric muaj peev xwm thiab kev tsim grate los pab txhawb kev siv ob qho tib si pebble-crushing Circuit Court siv thiab SAG zeb muaj peev xwm. Mill throughput yog maximized nrog plhaub lifters ntawm qhov sib piv ntawm 2.5: 1 thiab 5.0: 1. Qhov kev piv txwv no tau teev tseg yam tsis siv rau lub ntsej muag lub ntsej muag; Ntawm qhov sib npaug sib npaug-rau-qhov siab qhov sib piv, cov neeg nqa khoom nrog lub ntsej muag lub ntsej muag ntau dua yuav muaj teeb meem ntim tsawg dua thaum tshiab tab sis muaj kev hnav ris tsho ntau dua li cov uas muaj lub ntsej muag lub ntsej muag. Pulp lifter tsim tuaj yeem yog qhov tseem ceeb rau SAG mills, tshwj xeeb tshaj yog rau cov zeb loj. Tag nrho cov zeb loj loj nce, qhov yuav tsum tau muaj peev xwm ntawm cov pulp lifters loj hlob proportionally rau zeb ntim.