-

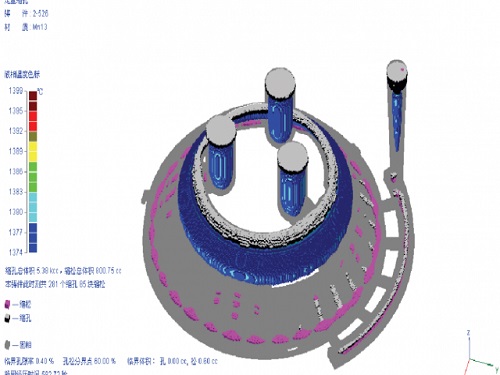

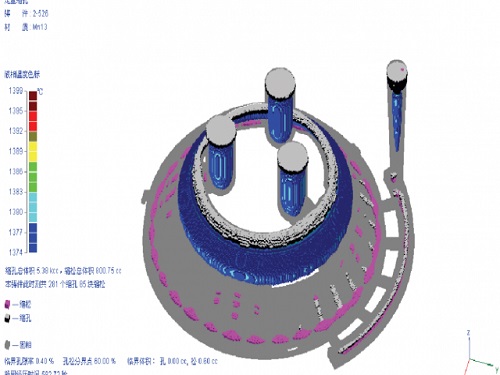

Abrasion analysis and optimization design of cone crusher liners in hydraulic cone crusher

Abrasion analysis and optimization design of cone crusher liners in hydraulic cone crusher Cone crusher cavity and cone crusher liners material are the most major factors affecting the abrasion of the concave and mantle in the hydraulic cone crusher. We have a customer, who runs KP100 hyd...Read more -

Apron Feeder Pans Manufacture

Apron Feeder Pans Manufacture With the vigorous development of the industrialization of the mine, various types of crushing stations have emerged. Corresponding complete sets of equipment such as crushers and conveyors have been widely used, and the demand for related accessories and spar...Read more -

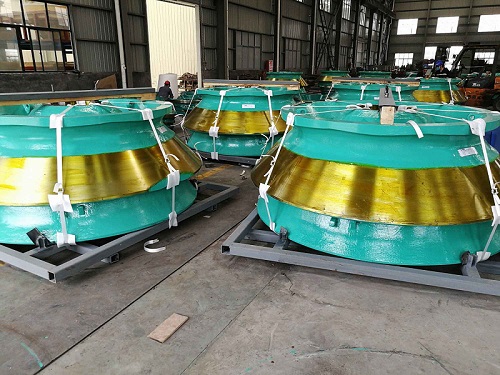

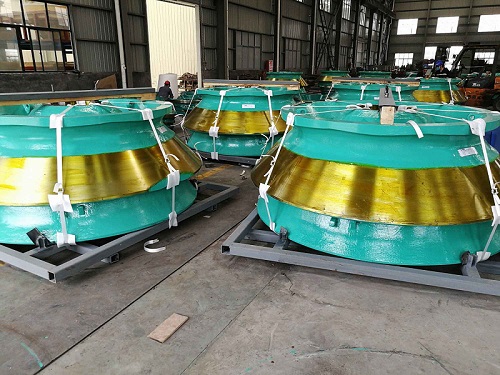

Cone Crusher Liners Production Methods

Cone Crusher Liners Production Methods Cone crusher liners include cone crusher mantle and cone crusher concave. Based on different situations, there are different production methods in casting those cone crusher wear parts. The main production methods include sand casting, V method casti...Read more -

Cone Crusher Liners Heat Treatment

Cone Crusher Liners Heat Treatment Cone crusher liners include cone crusher mantle and concave. The heat treatment is the most important step in casting cone crusher liners. How to control heat treatment? The advanced and convenient heat treatment tooling equipment is used, and the castin...Read more -

Cone Crusher Liners Melting Process

Cone Crusher Liners Melting Process Cone crusher liners are the most important wear parts for cone crusher. The cone crusher liners melting process is the key to get a long time span life. At present, many factories use intermediate frequency furnaces to melt high manganese steel. In orde...Read more -

When To Rotate Jaw Crusher Plates?

When To Rotate Jaw Crusher Plates? The perfect circumstance would be when even put on occurs throughout the jaw plate location, making use of all the manganese teeth, eliminating the demand to execute the “turn”, or modification manufacturing. This is difficult, however, due to the fact t...Read more -

When & How To Change Jaw Plates?

When & How To Change Jaw Plates? Jaw plates include fixed jaw plate and swing jaw plate, which are the main jaw crusher wear parts. They need to exchange very regularly. When & How to change jaw plates? When to change jaw plates? There are two situations need to change the jaw pla...Read more -

Crusher Jaw Plates Material Selection

Crusher Jaw Plates Material Selection Different crush stone, different work conditions, need to select the right material suit to cast crusher jaw plates. For example, Mn14 jaw plates can crush soft stone, but can not suit to crush hard stone, because it wears out speed too quickly...Read more -

New Design Ductile Iron Jaw Plates

New Design Ductile Iron Jaw Plates Analysis of the force and main failure forms of jaw plates The jaw crusher fixed jaw crushing liner produced by our company is mainly used for the rough and medium crushing of hard materials. During the working process, it bears the frictional force of ...Read more -

Jaw Crusher Liner Improved Design

Jaw Crusher Liner Improved Design Our customer uses a PEF2100*1500 jaw crusher to crush ironstone. More than 8.7 million tons of iron ore are broken each year, and 2.2 million tons of iron ore powder is produced. The jaw crusher liner is the main jaw crusher wear parts and the jaw crusher...Read more -

Large Cone Crusher Main Frame Shrinkage Improvement Practice

Large Cone Crusher Main Frame Shrinkage Improvement Practice Stone crushing machinery is widely used in many departments such as mines, smelting, building materials, highways, railways, water conservancy, and chemical industry. With the development of the world economy, the revival of min...Read more -

Prolonging Cone Crusher Liners Working Life

Prolonging Cone Crusher Liners Working Life In the current financial environment, the cost base is a significant consideration taking care of an effective quarrying company, as well as wear prices associated with cone crushers can be a significant expense center. This paper describes a te...Read more