Apron Feeder Pans Manufacture

With the vigorous development of the industrialization of the mine, various types of crushing stations have emerged. Corresponding complete sets of equipment such as crushers and conveyors have been widely used, and the demand for related accessories and spare parts has also increased. As the main conveyor on the crusher, The amount of component apron feeder pan is also gradually increasing,

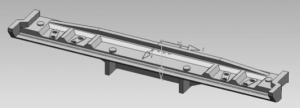

However, due to the difficulty of manufacturing, the apron feeder pans of major mines are all imported and the prices are high. The crusher chain plate developed this time is an ancillary product of Anshan Iron and Steel Mining Company’s crusher. The crusher is the key equipment for mining operations. The continuous and stable operation has a great impact on the efficient and safe production of the mine. The indispensable and important components on it can withstand large loads and wear and have a broad market space. The structure of the apron feeder pan is shown in the following picture.

This apron feeder pans product details:

- Weight: 527kg

- Material: ZGMn13Mo

- Size: 2856*456*291mm

The apron feeder pans have the following technical difficulties:

- Most of the wall thickness is 48 mm, which is a thin plate condition. Pay attention to its deformation during casting and heat treatment;

- To accurately ensure the dimensional accuracy of the arc at the assembly place and 8 holes;

- After molding, the angle control of the three trial installations must be guaranteed.

How to determine the appropriate casting process and design appropriate heat treatment equipment to ensure the quality of castings and the effects of arcs and angles, has become a difficult and critical point for apron feeder pans casting and heat treatment.

Apron feeder pans casting process design

Casting process

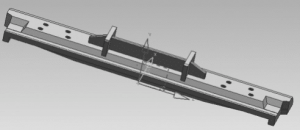

In order to ensure that the molten steel flows into the cavity quickly and smoothly, the inner gate of the casting is flat and evenly distributed on one side of the casting. A riser is placed at the corresponding gate position to ensure that the slag gas in the molten steel is removed in time and is higher than the riser Air vents are placed at the root to prevent casting from being under-cast, as shown in the figure.

Selection of main parameters

- Selection of casting scale. Combining the structural characteristics of the casting and the characteristics of the high-manganese steel material, the scale of the casting was selected to be 2.7%. In accordance with the actual production conditions of the company, the resin sand molding was used. At the same time, in order to ensure the accuracy and surface quality of the casting, prevent sticking on the surface and corners Sand, apply chromite sand on the surface and corners of the casting, and brush with magnesia powder coating.

- Selection of casting draft angle. Since the casting is used as a blank, its size is relatively tightly controlled. In order to avoid damaging the surface of the sand when the mold is raised after modeling, it is conducive to the production of high-quality castings. The draft angle is selected from 0 ° to + 3 °.

- Pouring temperature. During the pouring process, the temperature is too high, the solidification shrinks greatly, and the casting is prone to defects such as shrinkage and loosening, coarse grains and sticky sand. If the temperature is too low, it may easily cause insufficient pouring, cold insulation, and under-casting due to thin walls and other defects. Therefore, the appropriate pouring temperature is to use a slightly lower temperature on the premise of ensuring that the molten metal fills the mold cavity. Considering the heat loss during the molten steel transfer process and the casting itself, the casting temperature is selected to be 1 410 ℃ ~ 1 440 ℃.

Apron feeder pans mold

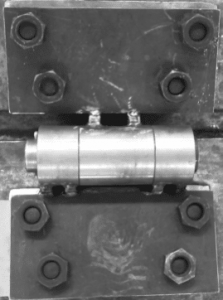

Aiming at the manufacturing difficulties of the apron feeder pans, by using metal molds (as shown in the figure) instead of wooden mold modeling, the accuracy and flatness of the critical dimensions of the casting length are guaranteed, and the deformation of the casting caused by the model deformation problem is prevented from the source. Guarantee the quality of the entire casting surface.

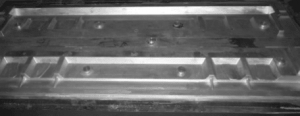

Apron feeder pans heat treatment tooling design

Aiming at the structural characteristics of the apron feeder pans castings, in order to prevent the deformation after the water-toughening treatment, a special heat treatment tool is specially designed. As shown in the figure, the two chain plate castings are interspersed with each other to form a pair of forms. The base tray type is used below to support the whole. Casting and ensure the stability of the casting during the whole process. The clamps are used on the top. The clamps are placed in the easy to deform and weak places for fastening. The internal cavity is blocked by a suitable baffle. This structure design can both To ensure the smoothness of the casting as a whole, and to ensure that the cooling water can completely cool the casting during the water-toughening treatment. Through this heat treatment tool, the deformation degree of the heat-treated casting meets customer requirements, and the deformation is not greater than 0.35: 100.

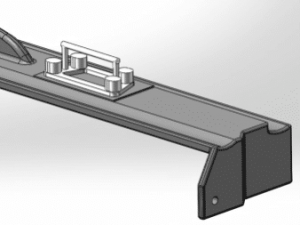

Design of assembly fixture and angle fixture

In combination with the actual use of the apron feeder pans, in order to ensure the precise alignment of the apron feeder pans with the lower chain link during use, a detachable inspection fixture is designed according to the 8-hole size of the chain link to ensure that the positions of the 8 holes at both ends of the apron feeder pans are the first time. The registration is accurate during the trial installation. The schematic diagram of the fixture is shown below.

The rotation of the apron feeder pans is completed by the driving wheel dialing the pin hole between the rail links to complete the transportation process. As shown in the figure, when apron feeder pans rotate, a certain angle (147 °) must be formed between the two positions of the driving wheel. In order to ensure that the rotation angle is appropriate, an angle test fixture is designed according to the use conditions on site, as shown in the figure. The angle test is carried out by using the angle test fixture. The rotation angle meets the requirements of the drawing and reaches 147 °, which ensures the normal rotation of the apron feeder pans in the subsequent.

Through the analysis of the technical characteristics and difficulties of the apron feeder pans casting, the use of metal molds in production solves the casting deformation caused by the mold deformation, and also guarantees the accuracy of key dimensions; the design and use of heat treatment tooling enables the long and thin plate conditions to be well controlled Heat treatment deformation problems; the use of assembly inspection tools and angle test inspection tools to ensure the accuracy of key assembly positions of chain plate castings. The domestic production of apron feeder pans was successfully realized, and qualified products for customers were produced. According to customer feedback, the apron feeder pans castings produced this time can completely replace imported castings in use. It provides production experience for the future production of such castings.

Mr. Nick Sun NICK@XZHUAGANG.COM

Post time: Oct-30-2020