Jaw Crusher Liner Improved Design

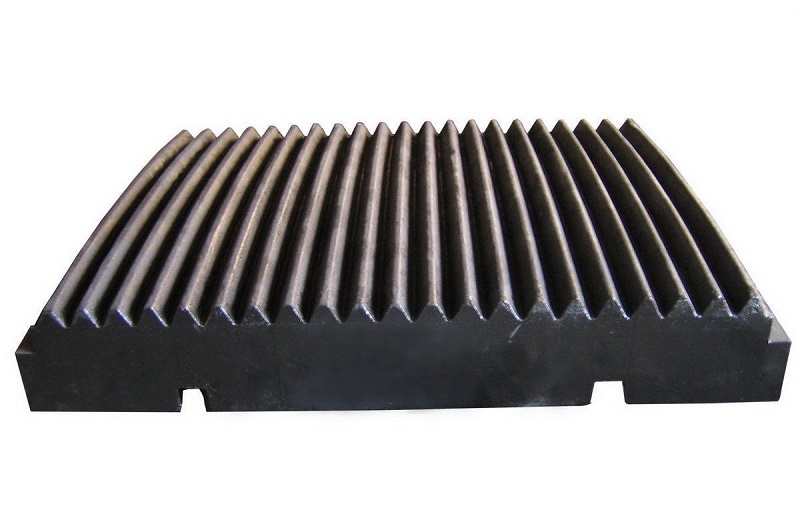

Our customer uses a PEF2100*1500 jaw crusher to crush ironstone. More than 8.7 million tons of iron ore are broken each year, and 2.2 million tons of iron ore powder is produced. The jaw crusher liner is the main jaw crusher wear parts and the jaw crusher liner has frequent failures during use, has a short service life, and seriously affects production.

Problems in the use of jaw crusher liner

The jaw crusher liners are made of ordinary high-manganese cast steel ZGMn13CrMo and have a thickness of 170 mm. The main problems are: the jaw crusher liner is easy to loosen or fall off during the crushing of iron ore, which causes the crusher to have accidents such as overload, plugging and scratching the rubber band during the operation; the strength and rigidity of the lining board are insufficient. Short life; Manual adjustment of the size of the ore outlet, low efficiency, and high labor intensity.

Improved design of the jaw crusher liner

Structural improvement

(1) On the premise that the quality of the moving jaw and fixed jaw lining is basically unchanged, and the strength and rigidity meet the requirements of ore breaking, a hollow weight reduction hole is designed on the back of the lining; increase the thickness of the ore breaking surface of the lining, The thickness of broken ore is increased by 80 mm, and the thickness of fixed jaw lining is increased by 80 ~ 110 mm.

(2) Design reinforcement ribs on the back of the lining board to increase the strength and stiffness of the lining board body, meet its requirements for breaking stress, and prevent the lining board from cracking.

(3) Design reinforcement ribs around the fixing bolt holes on the back of the lining board to increase the strength and rigidity of the part.

(4) In order to prevent the lining board from loosening, two holes for anti-loosening clamps are designed on the back of the lining board; correspondingly, anti-loosening fixing clamps are welded on the jaw crushing motor jaw body.

(5) Design lifting holes in the hollow lining.

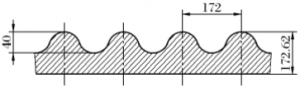

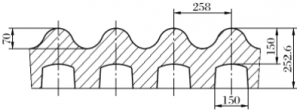

(6) Establish a mathematical model to improve the wave shape, wave height and breaking capacity of the jaw crusher lining. The waveform size of the original liner is peak radius 40 mm, height 40 mm, and peak spacing 172 mm (see figure); the improved liner waveform size is peak radius 70 mm, height 70 mm, and peak spacing 258 mm (see figure). After the waveform size of the liner has been improved, the squeezing, bending and splitting effects of the movable jaw and fixed jaw liner on iron ore, as well as the crushing bite force and ore braking efficiency, have been improved.

(7) On the adjusting horn on the back of the movable jaw lining board, design a hydraulic automatic adjustment of the discharge port device-a multi-interface hydraulic system to reduce the labor intensity of workers and realize the automatic adjustment of the size of the discharge port.

Material improvements

(1) The material of the liner is changed from the original ZGMn13CrMo high-manganese steel to the wear-resistant, impact-resistant, high-hardness ZGMn18Cr2 high-manganese steel. The shock absorption energy akU of the liner is increased from the original 40 J / cm2 to more than 120 J / cm2, the hardness is increased from 30 HRC to more than 40 HRC, the degree of work hardening is higher, and the wear resistance is also greatly improved.

(2) Nickel alloy component is added when casting the liner to improve the hardenability and aging treatment to improve the hardness and wear resistance of the liner.

(3) Increase the chromium content in the material of the lining to 2% to enhance the ability to form high hardness austenite carbides, thereby improving the wear resistance and service life of the lining.

The new jaw crusher liner results

In March 2010, the improved jaw crusher liner passed the iron ore heavy-duty extrusion, impact and abrasion test at Ekou Iron Mine. After more than half a year of field use, it has been proved that the crusher is operating well and the liner The impact toughness is increased by 3 times, the hardness is increased by 33%, and the service life is increased by 2 to 3 times.

Mr. Nick Sun NICK@XZHUAGANG.COM

Post time: Oct-30-2020