Chrome Moly Alloy Steel Mill Liner

Short Description:

Product Description

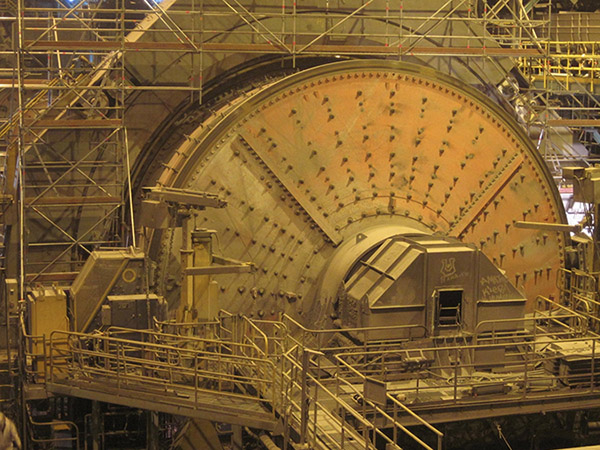

SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner from H&G use Cr-Mo materials (AS2074 Standard), SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner provides superior impact and wear resistance in all semi-autogenous milling applications.

To choose the right material for the right application is our mission , we are always working together with our customer to achieve this .The right material is upon to:

1. The mineral ground

2. Milling data information

3. Maximum grinding media diameter (mm)

4. Grinding media filling degree (%)

In general, Item M1 used for high impact condition ,P1 used for low impact condition. It shall change according to your mineral processing.

Specification Available

|

Code |

Chemical Elements(%)SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 |

0.4-0.7 |

0.6-1.0 |

1.8-2.5 |

0.25-0.5 |

0-0.5 |

≤0.04 |

≤0.06 |

|

M1 |

0.3-0.45 |

0.4-0.7 |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 |

0-0.5 |

≤0.04 |

≤0.06 |

Physical Property & Microstructure

|

Code |

Hardness(HB) |

Ak(J/cm2) |

Microstructure |

|

P1 |

325-375 |

≥50 |

P |

|

M1 |

350-400 |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Note: Adjust the chemical content or add other alloying elements of SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Our Advantage

At H&G Casting, we engineer innovative designs, tailored especially for every customer. Our SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner are manufactured to the highest industry standard for Autogenous Grinding(AG), Semi-Autogenous Grinding(SAG), Primary / Secondary and re-grind rod or ball mills. MGS Casting mill lining system designed by our highly trained, and dedicated team throughout the world has taken your entire comminution circuit into consideration. Supporting our front line Mill Engineers is a large team of extremely specialized design engineers, material chemists, manufacturing and logistics experts responsible for delivering exceptional service.

Optimal mill designs engineered by our team take into consideration service life; grind & power efficiency and ore characteristics, along with costumer circuit constraints both up and downstream of the mill lining.

HG Casting had success to use ASTM 2074/L2B alloy steel to manufacture AG/SAG mill liners. Under this material, our mill liners span life can be obviously improved. Our Australia customers had ordered more than 10,000 tons per year of this material mill liners.

As a casting foundry, HG Casting also has own SAG Semi-Autogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner design. In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be considered. Each of these topics has had a considerable amount of research, and numerous case studies of evolutionary liner design have been published. Based on experience, mill liner designs have moved toward more open shell lifter volumetric capacity and a grate design to facilitate maximizing both pebble-crushing circuit utilization and SAG mill capacity. Mill throughput is maximized with shell lifters between ratios of 2.5:1 and 5.0:1. This ratio range is stated without reference to face angle; At equivalent spacing-to-height ratios, lifters with greater face angle relief will have less packing problems when new but experience higher wear rates than those with a steeper face angle. Pulp lifter design can be a significant consideration for SAG mills, particularly for large mill. All mill sizes increases, the required volumetric capacity of the pulp lifters grows proportionally to mill volume.

Semi-autogenous grinding mill liner also called SAG mill liner, Autogenous grinding mill liner also called AG mill liner. Since the 2014 year, H&G Machinery has had become one of the largest AG/SAG mill liner manufacturers from China. No matter which material you want, manganese steel or Ni-hard steel or Cr-Mo steel or alloy steel; No matter which type of your mill liners need. wave shape or raised edge shape or stepped shape; H&G Machinery is your first choice.

Which Choose H&G Machinery’s AG/SAG Mill Liners?

- Rich experience. H&G Machinery supplies more than 10,000 tons of various kinds of mill liners.

- Various material. We offer different materials to suit different work conditions. Such as manganese steel, Ni-hard steel, Cr-Mo steel, and other alloy steels.

- Complete QC system. H&G Machinery supply a complete quality control system and records. You can check all the documents and records when you visit us or we send them to you.

- OEM service. H&G Machinery can manufacture your liners by your design or our engineer design.

AG SAG Mill Liner Function

Semi-autogenous grinding and autogenous grinding is a powder mill with a large cylinder diameter and a slow rotation. The material is fed into the mill through the hollow journal at the feeding end. Under the interaction of the materials, the material crushed to a certain fineness passes through the discharge The hollow journal at the end is discharged out of the machine. The liner is an important part of the grinding machine.

- The lifting liner lifts the material to a certain height, the impact of the free fall, and the friction effect between the friction between the materials, so that the materials are crushed and finely ground.

- The shape of the end cover lining board is relatively special. The bulk materials are added through the feeding port. The small pieces of material fall uniformly on the bottom center of the cylinder along the surface of the wave lining and then diffuse to both sides, while the large pieces of material have greater kinetic energy. : The projectile point always tends to the far side, but part of it will inevitably collide with the two sides of the wave lining. Due to the counterattack effect of the wave lining, it can prevent the material from being “segregated” in the axial large and small pieces, so that the large pieces of material can be evenly distributed. The coarse material returned from the discharge end along the lower side, like the newly added material block, evenly falls on the center of the bottom of the cylinder and then diffuses to both sides. The large and fine-grained materials move in the opposite direction along the axial direction at the bottom of the simplified Chinese, so they have a grinding effect.

- Both the lifting T-shaped lining plate and the wave plate have the function of wedging the block. With the rotation of the mill, the position of the block increases, and the compressive force quickly disappears and becomes a tension when the “arched” bridge moves upward and collapses so that the instantaneous stress generated by the continuous reciprocating motion will cause the block The monomers are separated, resulting in grinding.

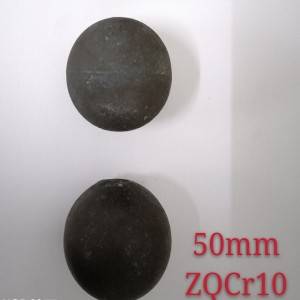

AG/SAG Mill Liner Material Selection

Different crushed material, different working conditions need different material liners to suit. In order to meet the requirements for customer AG or SAG mill liners, the materials of large mill liners are mainly high manganese steel, high alloy white cast iron, high carbon chromium-molybdenum steel, medium carbon chromium-molybdenum steel, etc. The matrix structure includes austenite, martensite, bainite, and pearlite.

H&G Machinery supplies the following material to cast your AG or SAG mill liners:

High Manganese Steel

High manganese steel is a traditional material for abrasion resistance and mill lining. It is widely used in various wear conditions because of its remarkable work hardening effect. The reason why the high manganese steel lining plate has a long service life is that the large ball mill has a slow speed and a large impact force between the grinding ball and the ore. The work hardening effect of the high manganese steel is significant, and the relative between the ore and the lining plate The speed is small. However, high manganese steel also has a fatal weakness, that is, in the case of large impact, due to its low yield strength, it is easy to rheology, resulting in large deformation of the liner, difficult to disassemble the liner, and the bolt will be broken in severe cases.

Alloy white cast iron

The representative material of alloy white cast iron is high chromium cast iron, and the Cr content is usually greater than 12%. Because it contains isolated rod-like high-hardness M7C3 type carbides, it shows higher hardness and better impact toughness (compared to white cast iron), and it has been widely regarded as a new generation of wear-resistant materials, and It has been applied to the liner of ball mill. However, the impact toughness of high-chromium cast iron is still relatively low (usually 5~7 J/cm2), so high-chromium cast iron is only suitable for the mining of small-size liners and large-size liners in cement mills Wet small-diameter mills (diameters below 2.5 m) are not suitable for large-diameter mills with large impact strength, especially large SAG mill.

Alloy Steel

Alloy steel as a wear-resistant material has also achieved good results in practical applications. The main reason is that the carbon content of alloy steel and the types and contents of alloy elements can be varied within a large range. With different heat treatment processes, The structure and properties of alloy steel can be adjusted within a relatively large range to obtain better comprehensive mechanical properties and meet the requirements of different working conditions. Research and practice have shown that alloy steel is suitable as a mill liner for large self-grinding machines and semi-self-grinding machines, as shown in the table:

| Relative Life Of Alloy Liner Used In AG Mill | ||||||

| Alloy Steel Species | Ball Media | Diameter 11.0m AG Mill Shell liner |

Diameter 8.2m AG Mill Shell liner |

Diameter 9.8m AG Mill Shell liner |

Diameter 9.8m AG Mill End liner |

Diameter 14.4m AG Mill End liner |

| Austenitic 12%Mn steel | 0.64 | / | / | / | / | / |

| Pearlite 0.8%C Cr-Mo alloy | 0.7 | / | 0.46 | 0.48 | / | 0.54 |

| Martensite 0.4%C Cr-Mo alloy | 0.77 | 0.63 | 0.67 | / | 0.73 | 0.81 |

| Martensite 1.0%C Cr-Mo alloy | 0.85 | / | / | / | / | 0.94 |

| Martensite 2%Cr-4%Ni iron alloy | 0.83 | 0.67 | / | / | / | / |

| Martensite 8%Cr-4%Ni iron alloy | / | 0.79 | / | / | / | / |

| Chromium-molybdenum cast iron | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

It can be seen that the martensitic Cr-Mo alloy steel lining plate has a good use effect in the self-grinding machine, followed by the pearlite Cr-Mo alloy steel lining plate. Pearlite Cr-Mo alloy steel lining has been widely used in semi-automatic mills. Although its wear resistance is slightly worse than martensitic Cr-Mo alloy steel, its impact toughness is higher than martensitic Cr -Mo alloy steel, so it is suitable for large semi-self-milling machine with relatively large impact.

AG/ SAG Mill Liners Types

Based on the use area, it can be divided into:

- Lifting Liner

- End Liner

- Shell Liner

AG/SAG Mill Liners Shapes

The shape of the AG/SAG mill liners include:

- Flat liner. For fine grinding silo, the rising height of the grinding body depends on the static friction coefficient between the lining plates.

- Bead liner. Used in the first bin, it can make the grinding body rise higher and have larger impact energy.

- Convex ribbed liner. Similar to bead liner.

- Wave liner. Suitable for baseball grinding.

- Ladder liner. It is suitable for crushing silo and it is widely used.

- Hemispherical liner. Suitable for crushing silo.

AG/SAG Mill Liners Installation

Preparation Work

- Prepare all need to replace mill liners.

- Check the shape and size of all liner plates, remove hair wings, casting slag, etc.;

- Be prepared to replace the required bolts, nuts and washers and other accessories;

- Check carefully whether lifting appliances, appliances and rigging are safe and reliable.

- Prepare 36V safety power supply for construction lighting in the tube;

- Before the mill is stopped, there must be enough minerals in the barrel suitable for the entry and exit of the liner before stopping.

- All construction personnel must wear labor protection supplies including hard hats, masks, and non-slip shoes before entering the site.