Grinding Ball Mill SAG Mill AG Mill and Rod Mill Use High Mn Steel Ball Mill Liner

Short Description:

Product Description

Manganese Steel Ball Mill Liner in general refers to a kind of casting steel with the Manganese content at 11%~22%, the carbon content at 0.9%~1.5%, mostly higher than 1.0%. Under low impact load, Manganese Steel Ball Mill Liner can achieve HB300~400, Under high impact load, can achieve HB500~800. Different impact load, the Manganese Steel Ball Mill Liner's surface hardening layer depth can be up to 10~20 mm. High hardness of hardening layer can resist the wear of grinding media. Under the condition of strong impact abrasive wear, Manganese Steel Ball Mill Liner has excellent anti-wear performance, so Manganese Steel Ball Mill Liner widely used in mining, aggregates, coal industries as wear-resistant parts.

Note: Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 12 to 25%.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

|

Manganese Steel Ball Mill Liner |

0.9-1.5 |

0.3-1.0 |

11-22 |

0-2.5 |

0-0.5 |

≤0.05 |

≤0.05 |

≤0.05 |

Physical Property & Microstructure

|

Name |

HB |

Ak(J/cm2) |

Microstructure |

|

Manganese Steel Ball Mill Liner |

≤280 |

≥100 |

A+C |

|

A:Austenite C:Carbide |

|||

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

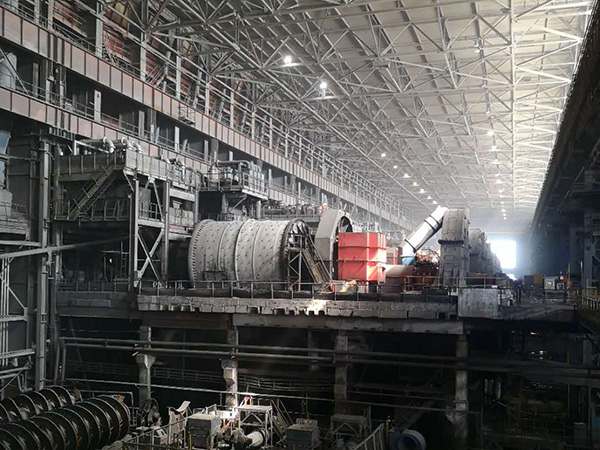

Application

Among the great advantages of the ball mill liners of the HG Casting, one can mention the following:

- It is much less weight than steel ball millliners. This has caused the wear of the bearings to be minimized and the milling torque at the start of the ball mill is at its best.

- Using lightweight combinations for ball mill liners has made it easy to install and operate them, and you do not need special tools or machines or qualified people to do this, nor do you need to use the You will not have to.

- In the production of rubber ball mill linings, the rubber ball mill liners can easily be used for other purposes and applications, as these ball mill liners can be easily used as a replacement for rubber and metal fittings and Or other resistant rubbers used as a composites ball mill liners for other equipment and purposes.

- In the production of these ball mill liners, it has been attempted to remove the blinding of grate plates that significantly increase the productivity of ball mills.

- Also, due to the use of best rubbers, the volume of the device has dropped dramatically, which will reduce the volume of the factory sound and facilitate working conditions.

Ball mill liner parts

The HG Casting also started to produce all kinds of lifter bars, shell sheets or plates and head plates used in ball mill liner as the main components of these devices to be generally used as suitable alternatives for ball mills with High and guaranteed quality.

Shell Plates

Each sheet of Shell plate have its own thickness and cannot be considered the same. Shell plate are used to balance the mill capacity and to maintain the life of the ball mill and its higher efficiency.

Lifter Bars

Lifter bars should be tailored to the type of ball mill and type of product and be designed with a wide range of profiles or even dimensions. In fact, the lifter bars should be able to increase the efficiency of an ore operation and to maximize the grinding of the ball mills. Having a high quality for the lifter bars is of paramount importance because make it easy to raised up and down the ball mill liner with the help of lifter bars.

Head Plates

Bear in mind that we, using the best experts and equipment and machinery in the HG Casting, have been designing and manufacturing a variety of special plates for ball mills and ball mill liners that can be easily installed depending on the type and structure.

The ball mill is used to make sure that your ball mill liner will last for maximum durability and high quality and outstanding performance. For this purpose, in the HG Casting, we use the finest custom rubbers for the production of ball mill plates, which, along with its high quality and durability, have the characteristics of high wear and tear resistance, high resistance to acid and chemical substances and types other materials are easily installed and installed.