Application of Insulating and Exothermic Riser In Casting High Manganese Steel Mining Machinery Wear Parts

At present, high manganese steel castings are in great demand. Its main products are cone crusher liner, jaw plate, liner plate, blow bars, SAG mill liner, mill liner, etc. With the continuous improvement of the quality requirements of castings, some foundry has also continuously improved the casting process. Among them, the shrinking riser has also changed from the initial selection of sand riser to the use of ordinary insulation riser, and then to the current Insulating and Exothermic Riser technology, which is effective The tendency of shrinkage, shrinkage, and cracks in castings has been solved, and the casting yield has been continuously improved, and subsequent cleaning costs have been significantly reduced, and significant economic benefits have been achieved.

The insulating and exothermic riser has the characteristics of initial insulation, intermediate heating, and lasting insulation for a long time, so it has the best shrinkage effect, which is very suitable for the high shrinkage of high manganese steel. The time is greatly extended, and the filling efficiency is higher. Compared with ordinary insulation riser, insulating and exothermic riser has the following advantages:

- Effectively solve defects such as shrinkage and shrinkage of castings, and improve the density of castings;

- Significantly reduce defects such as slag inclusions and pores in castings;

- Significantly improve the feeding efficiency of the riser and the casting process yield, and improve the economic efficiency of the enterprise;

- Reduce feeder cleaning costs and welding repair workload.

Application of Insulating and Exothermic Riser In Casting Mining Machinery Wear Parts

At present, the production process of high manganese steel castings mainly adopts the following two production processes. One is that the surface quality of the casting is not high, and most of them use hardened water glass sand molding technology. The other is the production process of basic phenolic self-hardening resin sand. This type of casting generally requires high requirements. Most export castings use this process. . In the design of the riser process, some castings use ordinary insulation risers. At present, more and more manufacturers have started using heat insulation risers. The practice has shown that the use of a heat-preserving riser sleeve can reduce the weight of the metal liquid in the riser, thereby improving the process yield of the casting. In addition, the casting has few problems such as shrinkage and shrinkage, and most of the risers can be knocked off with hammers, reducing The tendency of cracks in the casting caused by the cleaning of the riser.

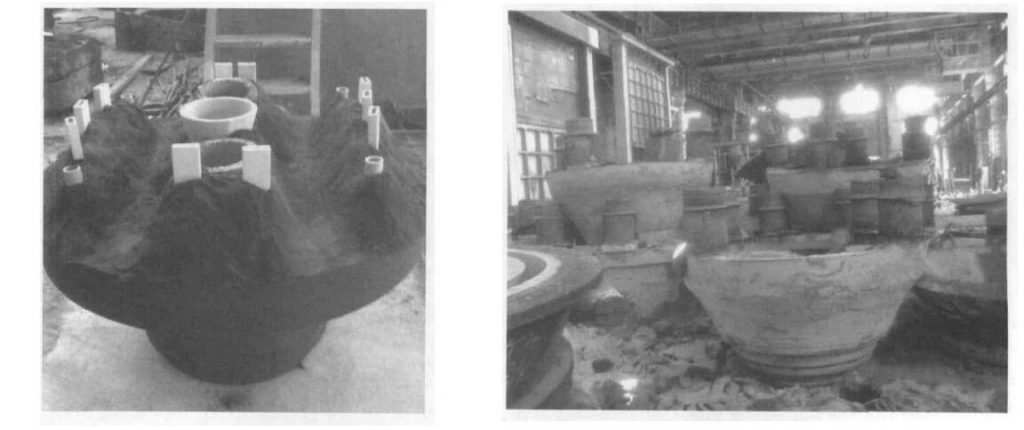

Application of Insulating and Exothermic Riser In Casting Cone Crusher Wear Parts

Cone crusher wear parts include cone crusher concave and cone crusher mantle. Initially, the casting was produced using a common heat preservation riser and covering agent production process, and some defects such as shrinkage pores appeared in the casting. Due to the large size of the riser, the workload of removing the riser was large, and the main reason was high-manganese steel castings. Cracks easily occur in gas cutting. Later, the insulating and exothermic riser was used, the quality of the casting was significantly improved, and the riser can be easily removed without gas cutting. In this way, the crack defects that are easy to occur in the casting when the gas cutting riser does not occur. Based on the above advantages, the heat insulation riser It has been promoted one by one, and the comprehensive economic benefits of manufacturers have also been significantly improved.

Application of Insulating and Exothermic Riser In Casting Jaw Crusher Wear Parts

Jaw crusher wear parts include fixed jaw plate and movable jaw plate.

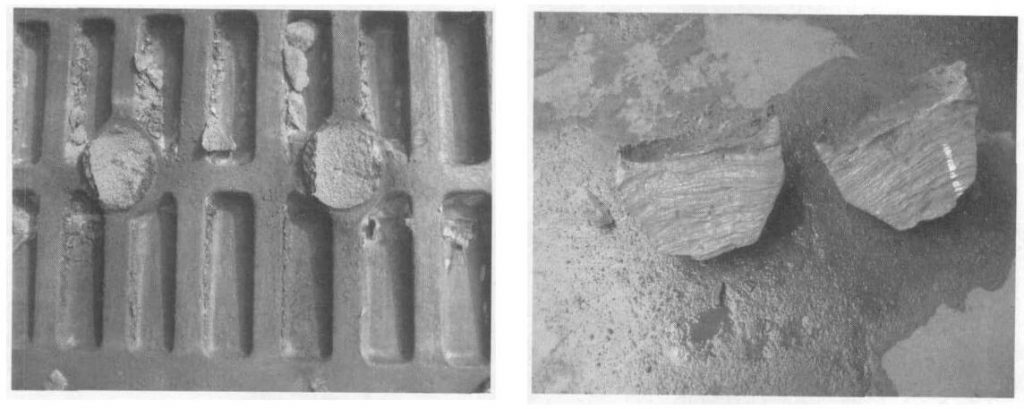

- Test part: Jaw plate, weight:1500kg, material: Mn18Cr2, Casting temperature: 1420-1440℃, Insulating and Exothermic Riser;

- The casting after the riser is smashed, the root of the riser is not loose, check-in the following picture;

- Cut the riser and observe the effect of the riser filling;

- Safe height measurement of risers.

From the above analysis of the riser, the riser has a good effect of shrinking, there is almost no shrinkage problem inside the riser, the riser is safe, the root tissue of the riser is dense, and there is no shrinkage or shrinkage.

The application of the insulating and exothermic riser in the field of wear-resistant high-manganese steel castings of mining machinery has obvious effects, improving the quality of castings and market competitiveness. Its successful experience has a strong promotion value, which is worthy of reference and learning from other similar manufacturers.

In addition to a large number of applications in the field of wear-resistant high-manganese steel castings for mining machinery, insulating and exothermic risers are also widely used in locomotive castings, such as bolsters, side frames, and other automotive castings, such as axles, turbine casings, engines, and exhaust Manifold pump and valve castings and engineering machinery castings have played a very good role in this type of castings.

H&G Machinery is the specialist in casting crusher wear parts, shredder wear parts and mill liners with insulating and Exothermic Riser!

Mr. Nick Sun NICK@XZHUAGANG.COM

Post time: Oct-23-2020