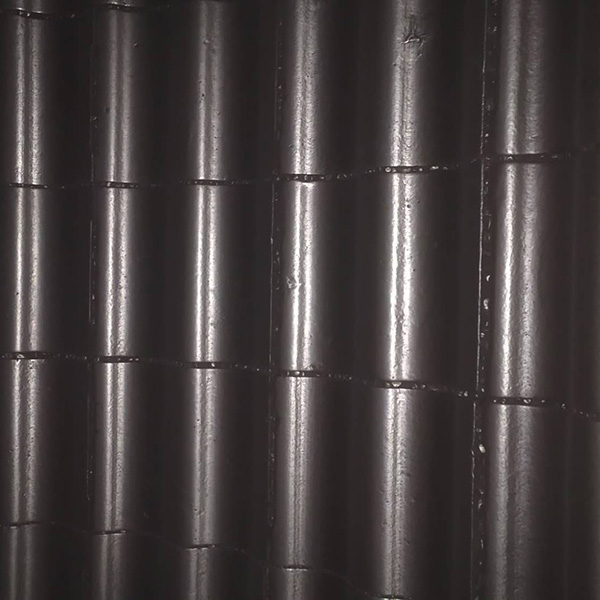

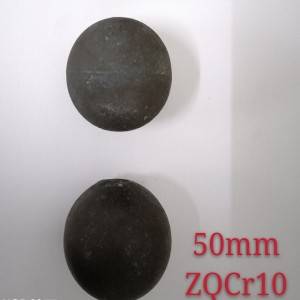

26%Cr 28%Cr High Cr egweri Mill Liner

Nkọwa dị mkpirikpi:

Nkọwa ngwaahịa

White Iron Ball Mill Liner n'ozuzu na-ezo aka na alloy white iron nwere ọdịnaya chromium na 12% ~ 26%, ọdịnaya carbon na 2.0% ~ 3.6%. Ihe pụrụ iche nke White Iron Ball Mill Liner bụ na ụdị M7C3 eutectic carbide micro hardness bụ HV1300 ~ 1800. White Iron Ball Mill Liner's eutectic carbide na-ekesa na ntọala, martensite (nzukọ matrix metal siri ike), na netwọk kwụsịrị na iche, nke na-ebelata ikewa nke mmetụta matrix. N'ihi ya, elu chromium Ball Mill Liner nwere ike dị elu, ike siri ike na njirimara nguzogide dị mma, nke a na-ejikarị eme ihe na Ngwuputa, ciment na ụlọ ọrụ ike.

A na-atụ aro White Iron Ball Mill Liner ka ọ na-eji ọnọdụ arụ ọrụ dị obere dị ka:

1. Belt ebu liner maka Ngwuputa ụlọ ọrụ.

2. Osisi Cement Ball Mill.

3. Chemical Industry Ball Mill.

Ihe kemịkalụ

|

Aha |

Ihe kemịkalụ (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ku |

P |

S |

|

|

High Cr Ball Mill Liner Cr26 |

2.5-3.3 |

0-0.8 |

≤2.0 |

23--28 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

|

High Cr Ball Mill Liner Cr15 |

2.3-3.3 |

0-0.8 |

≤2.0 |

14--18 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

Ngwongwo anụ ahụ & Microstructure

|

Aha |

HRC |

Ak (J/cm2) |

Microstructure |

|

High Cr Ball Mill Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C- Carbide A-Austenite |

|||

Mara: Gbanwee ọdịnaya kemịkalụ ma ọ bụ gbakwunye ihe ndị ọzọ na-eme ka ọ bụrụ ihe na-eku ume nke Ball Mill Liner dịka mkpa ndị ahịa siri dị.

ngwugwu ngwaahịa

● Ngwongwo nchara, pallet osisi na igbe osisi

● Haziri dị ka mkpakọ ngwaahịa pụrụ iche si dị.

Ngwa

Anyị White Iron Ball Mill Liner na-ọtụtụ ebe na-egweri ogbo maka Ngwuputa ụlọ ọrụ, ciment ụlọ ọrụ, thermal ike osisi, akwụkwọ-eme akwụkwọ na chemical ụlọ ọrụ wdg.

Igwe igwe bọọlụ bụ ụdị igwe nri a na-eji egweri, ngwakọta na mgbe ụfọdụ maka ịgwakọta ihe eji eme ihe na usoro mgbakwasa ịnweta, agba, pyrotechnics, ceramics na nhọrọ laser sintering. Ọ na-arụ ọrụ na ụkpụrụ nke mmetụta na ihe mgbagwoju anya: Mbelata nha na-eme site na mmetụta dị ka bọọlụ na-adaba n'akụkụ elu nke shei ahụ.

Ihe igwe ihe igwe nwere oghere cylindrical shei na-atụgharị gburugburu axis ya. Axis nke shei nwere ike ịbụ kehoraizin ma ọ bụ n'obere akụkụ na kehoraizin. A na-ejupụta ya na bọọlụ. Mgbasa ozi na-egweri bụ bọọlụ, nke enwere ike iji ígwè (nchara chrome), igwe anaghị agba nchara, seramiiki ma ọ bụ roba. A na-ejikarị ihe na-egbochi abrasion dị ka manganese ígwè ma ọ bụ roba mkpuchi kpuchie elu dị n'ime shea cylindrical. Obere iyi na-ewere ọnọdụ na igwe igwe nwere akwa rọba. Ogologo igwe igwe ihe dị ka dayameta ya.

A bịa n'ihe igwe igwe igwe na-acha ọcha chrome moly, H&G Mill Liners lekwasịrị anya ihe a ogologo oge. Igwe igwe ihe igwe na-acha ọcha chrome moly anyị na-adị ogologo ndụ karịa ihe igwe igwe ihe ndị ọzọ.

A na-ahụta ihe nkedo a dị ka ihe kachasị emepụtara ma jiri ya mee ihe ruo taa maka nguzogide abrasion na Milling. A na-ejikarị ya eme ihe na igwe simenti na ụfọdụ n'ime igwe bọọlụ kachasị ukwuu n'ụwa yana ebe arụrụ ọrụ emebeghị ka ọ dị ugbu a.

Atụmatụ

- 600 ruo 700 BHN ígwè ọcha

- Nnukwu igwe igwe

- Ígwè a na-agbagharị agbagharị: nke a na-atụba dị ka ígwè ọcha, emesia ahụ adịghị ya mma, ma ọ bụ okpomọkụ na-agwọ ya, iji nye ductility. Ihe mejupụtara graphite nwere iwe n'ime

matriks a-ferrite ma ọ bụ pearlite - A na-ahụkarị na igwe igwe ciment

- Ejiri ya maka nguzogide abrasion

A bịa n'ihe igwe igwe igwe Ni-hard, H&G Mill Liners lekwasịrị anya ịtụba ihe a maka ndị ahịa anyị. Igwe igwe igwe Ni-hard iron anyị na-adị ogologo ndụ karịa ihe igwe igwe ihe ndị ọzọ.

Ni-Hard Cast Iron bụ nke amara nke ọma maka ịdịte aka na ịdị mma ya. Ihe ndị emere n'elu Ni-Hard bụ ndị na-eguzogide ọgwụ na ogologo ndụ ma e jiri ya tụnyere ígwè nkedo ndị ọzọ ma ọ bụ nchara dị nro. Ọdịnaya nickel na-abawanye site na nha ngalaba ma ọ bụ oge jụrụ oyi ma gbochie ngbanwe pearlitic nke nkedo.

Ihe a na-eji ụdị ihe a malite na Rod Mills na Ball Mills, ebe a na-ahụta mmetụta dị ala nke ọma maka ihe a na-emebi emebi ma na-eguzogide ọgwụ iji rụọ ọrụ nke ọma. Otú ọ dị, a na-ewere ya ugbu a dị ka ihe na-adịghị emezigharị n'ihi iji ígwè dị elu chrome na chrome moly white iron.

Atụmatụ

- Chromium na-agụnyekarị n'etiti 1.4-4% iji hụ na usoro carbon na-agbake na carbide, ọ bụghị graphite. (Na-emegide mmetụta graphitizing nke Ni);

- Nguzogide abrasion (nke a na-achọkarị ihe onwunwe nke ihe a) na-abawanye na ọdịnaya carbon, mana ike na-ebelata;

- Ihe mejupụtara martensite matrix, yana nickel alloyed na 3-5% iji gbochie mgbanwe nke austenite na pearlite;

- Nguzogide abrasion (nke a na-achọkarị ihe onwunwe nke ihe a) na-abawanye na ọdịnaya carbon, mana ike na-ebelata;

- Klas dị iche iche m pịnye Abrasion eguzogide; klaasị m ụdị B siri ike;

- Ngwa: N'ihi ọnụ ala dị ala, a na-eji ya eme ihe na ngwa Ngwuputa dị ka igwe igwe na-egweri bọọlụ na-egweri bọọlụ;

- Isi ike ihe a: 550 BHN

A bịa n'ihe igwe igwe igwe igwe dị ala, H&G Mill Liners lekwasịrị anya ịkwanye ihe a maka ndị ahịa anyị. Igwe igwe igwe igwe igwe anyị dị obere na-adị ogologo ndụ karịa ihe igwe igwe ihe ndị ọzọ.

Ihe a na-akpọkwa AS2074 L2B steel. A na-ejikarị ígwè a eme ihe maka igwe igwe igwe (AG, SAG na Ball) tupu mmegharị ahụ gaa n'ụdị ígwè carbon dị elu. Ọ nwere njirimara ejiji mara mma yana ụfọdụ nguzogide mmetụta, nke a na-ejikarị eme ihe maka mwepu grates ebe achọrọ nguzogide mmetụta dịtụ mma ma e jiri ya tụnyere carbon chrome moly steels dị elu ma ọ bụ maka ndị na-ahụ maka ngalaba dị gịrịgịrị.

Atụmatụ:

- Ejiri AG / SAG na igwe igwe bọọlụ;

- Ejiji mara mma na ụfọdụ nguzogide mmetụta;

- Ọdịdị Metallographic nke AS2074 L2B Steel bụ Pearlitic;

- Ọ dị mma maka ịpụpụ grates;

- Isi ike nke AS2074 L2B bụ HB310-HB380.

A bịa n'ihe igwe igwe igwe carbon chrome moly dị elu, H&G Mill Liners lekwasịrị anya ịkwanye ihe a maka ndị ahịa anyị. Igwe igwe igwe igwe anyị dị elu na-adị ogologo ndụ karịa ihe igwe igwe ihe ndị ọzọ.

Ihe a na-akpọkwa AS2074 L2C steel. A na-ewere ígwè a ugbu a dị ka isi ihe eji eme ihe maka igwe igwe SAG. Enwere ọnụọgụ dị iche iche nwere ma ọ bụ ihe dị iche iche carbon ma ọ bụ chrome. Ọdịiche dị iche iche na-enwekarị mmetụta na nha nke liner na oke akụkụ ya. A na-enwe mmepe na-aga n'ihu n'ime mpaghara a ka nha nke liners na-arị elu ihe ndị a na-enye site na ọkọlọtọ elu chrome moly steels.

Atụmatụ

- Ngwongwo nke ihe igwe igwe SAG dị obere C ma ọ bụ Cr-Mo Alloy steel, nke dabere na ọnọdụ ọrụ akọwapụtara nke igwe igwe SAG;

- Chromium na molybdenum abụọ n'otu n'otu na-abawanye ike nke ígwè alloy dị ala. Mmetụta synergistic dị mkpa, nke a na-akọwabeghị nke ọma, nwekwara ike ime mgbe a na-eji Cr na Mo n'ọnọdụ nke otu ihe;

- Ọdịdị metallographic nke AS2074 L2C Steel bụ Pearlitic;

- Chromium na-eweta iguzogide corrosion na oxidation, ike okpomọkụ dị elu na nguzogide abrasion. Molybdenum na-enyere aka ịnọgide na-enwe ike siri ike kpọmkwem ma na-abawanye nhịahụ okpomọkụ dị elu na ike na-akpụ akpụ. A na-emeso akara ule ndị a n'ozuzu okpomọkụ ka ọ bụrụ ihe ndị akọwapụtara;

- Isi ike ihe a: 325 ruo 380 BHN

Achọrọ nwụnye Ball Mill Liner

- Mgbe etinyere igwe ihe igwe, efere ngwụcha na mkpuchi mkpuchi cylinder ga-ejupụta na ngwa ngwa ciment 43.5MPa ike mkpakọ.

- Mgbochi na-edozi njedebe njedebe agaghị ekwe ka ngwa ngwa ciment zuru ezu, ma ọ ga-enwe ike ịtụgharị ma ọ bụ banye ma pụọ.

- Igwe ihe igwe bọọlụ bụ ntụzịaka n'ozuzu, ị ga-akpachara anya na ya n'oge echichi, emela azụ.

- Ogologo arc nke oghere okirikiri niile agaghị agafe 310mm, a ga-eji efere igwe were kewapụ ihe karịrị ya.

- Ọdịiche dị n'etiti liners n'akụkụ abụghị ihe karịrị 3 ~ 9mm.

- Ekwesịrị itinye interlayer dị ka ihe a chọrọ n'ichepụta n'etiti liner na elu ime cylinder. Ọ bụrụ na ọ dịghị ihe a chọrọ, ngwa ngwa ciment na ike mkpakọ nke 42.5MPa nwere ike jupụta n'etiti abụọ ahụ. Mgbe ngwa simenti ahụ tọchara, mee ka ihe nkedo ahụ sie ike ọzọ.

- Mgbe ị na-etinye liner na mpempe akwụkwọ rọba, mepee mpempe akwụkwọ rọba gbakwụnye 3 ruo 4 izu tupu echichi ka o kwe ka ọ gbatịa n'efu; mgbe ị na-eji mpempe akwụkwọ rubber, ogologo akụkụ nke mpempe akwụkwọ rubber kwesịrị ịgbaso ntụziaka axial nke cylinder, akụkụ dị mkpirikpi na-agbaso gburugburu cylinder ahụ.

- Jiri nlezianya lelee oghere mkpuchi nke liner na geometry nke mkpuchi mkpuchi, ma jiri nlezianya hichaa oghere flash, burrs, na protrusions na oghere mkpuchi mkpuchi na mkpuchi mkpuchi ka bolts wee banye kpamkpam n'ime ọnọdụ achọrọ.

- Ntọala zuru oke nke mkpuchi mkpuchi kwesịrị ịgụnye ihe mkpuchi na-egbukepụ egbukepụ, ndị na-ekpocha uzuzu, ndị na-ehicha ọkụ, mmiri mmiri mmiri, na mkpụrụ; iji gbochie ntapu uyi, ị gaghị echefu iji uzuzu uzuzu n'oge eji.

- Mgbe ị na-eme ka ihe mkpuchi mkpuchi sie ike, a ga-eji ihe mgbawa ike mee ihe maka ọrụ ahụ. Ekwesịrị ịgbatị bolts lining nke nkọwa dị iche iche dị ka ihe ndị chọrọ ike ike siri dị.